It’s no shock there’s been an industry shift from real to faux neon. LED alternatives are shatter-resistant and energy efficient. They’re more flexible and easier to install. And they never need their gases refilled. But that doesn’t necessarily mean they’re always the most durable or design-appropriate option, especially on historic buildings made iconic by their original signs’ authentic neon glow.

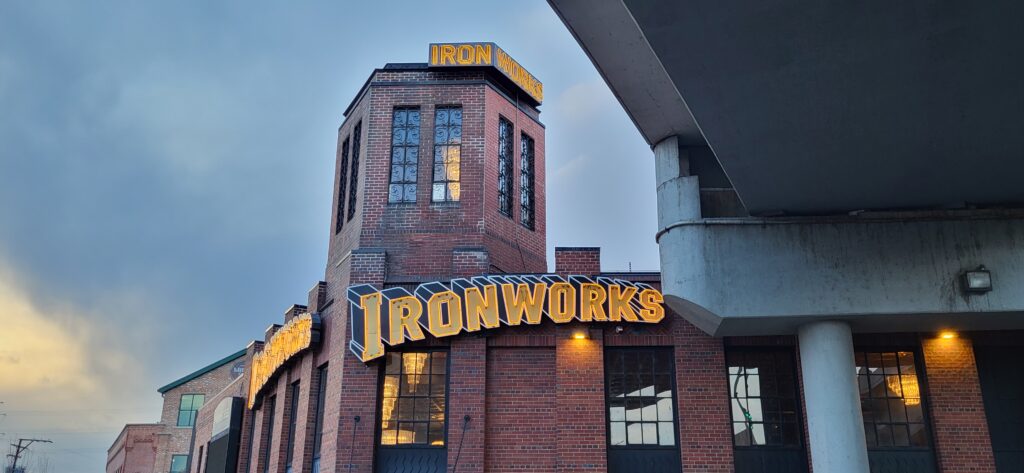

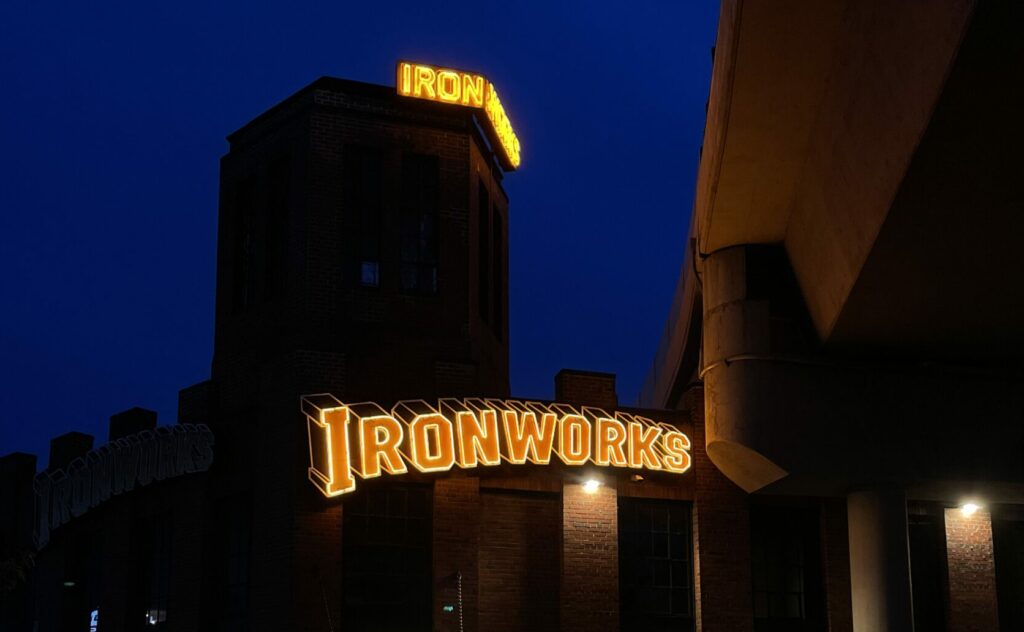

Morry’s Neon Inc. of Denver recently made its foray into what their team suspects will be a growing trend: retro retrofitting. Their client, Ironworks, is a private event venue in a 1903 brick building that was once home to Midwest Steel. A neon sign adorned the building for over 80 years before the property’s owner had LEDs installed in 2017.

“They were a problem from the start,” Ironworks Owner Joseph O’Dea says. “[We] went through several [power supplies], and finally in 2022, we had cracks in the LED … that were taking on water and shorting out. In looking at having the LED replaced, it was almost as much as the original install.”

O’Dea cold called one of the few neon shops left in the area: Morry’s. “He called wondering if we would work on the LED,” Morry’s Tina Weseloh and Todd Matuszewicz recall. They went to look at the signs and informed their new customer LED can’t be repaired, only replaced.

The UV from the sun had broken down the plastic channel and several of the modules were no longer working. “We knew that the sign had been neon before the LED, and asked if he would be open to it being neon again, since it had proven longevity,” Weseloh and

Matuszewicz say.

Morry’s used 390 feet of Noviol Gold neon in the four sets. “On many of these retro retrofits, the original design features are often just covered over, sometimes with plugs or plates or in this case, plates that had vinyl over the top of them,” Weseloh and Matuszewicz explain. “This can be a helpful guide to recreating the neon and to bringing the sign up to modern codes.”

As far as the change back to neon, O’Dea says, “[I] wish I would have done this originally as we would have saved significant cost. Our electric bill has not changed since we switched.”

So what can lighting shops do to get their clients interested in neon—or get into the real neon game if they’re not already? Start by presenting the option to customers. “After making the Ironworks neon again, the owner purchased two more large [neon] signs for another business he owned… So offering neon can lead to much more business,” Weseloh and Matuszewicz say. “It may not be feasible, economically, for lighting shops to have their own neon plant, but it can be quite profitable to sell handcrafted signage to their customers while subcontracting out the neon work to a qualified neon shop.”

Weseloh and Matuszewicz say one of the most effective sales techniques is hosting tours of their shop. It’s all about seeing the process. “We have hosted preservation commissions, sign brokers, entrepreneurs, small business owners, the general public, and one home schooled high schooler, along with TikTok influencers and HGTV,” they say. “All of them have left enamored with neon.”

There’s also been a resurgence of interest in real neon over the past several years. Weseloh and Matuszewicz reference the current makers movement with an uptick in craft breweries, artisanal distilleries, handsewn clothing and other homemade goods. “It has been our experience listening to visitors at the shop, that there is a warmth to neon that is lacking in LED,” they say. “A common refrain from visitors is ‘it just makes me feel so good inside, when I see a neon sign.’”

While convincing customers to choose real neon is relatively simple, preserving the craft within the industry is more of a challenge. “Many of the older tube benders learned to bend either by making channel letters or beer signs. Neither of those avenues are available any longer,” Weseloh and Matuszewicz explain. They say younger people interested in the craft must be persistent in finding apprenticeships. Otherwise, they’ll need to buy their own equipment, find a mentor (they recommend the Neon Makers Guild) and be fiercely dedicated to practicing their glass skills.

“It is a very difficult craft to learn,” Weseloh and Matuszewicz say. “However, announcing at a party that you are a neon tube bender is the best pickup line and party trick known to mankind. Seriously, it is a really unique, engaging, fascinating, rewarding pursuit. We wouldn’t be as passionate about it as we are if it weren’t.”