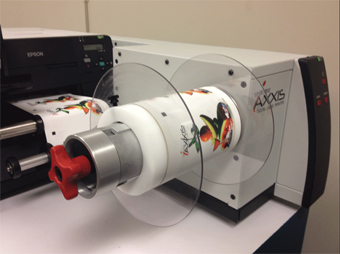

Digital Lollipop, an Australian digital label and sticker printing company founded by Tony Bogatie, has been producing quality products since they opened their doors more than a year ago. After working in the high-end flexo industry for eight years and watching technology advance, Tony saw the value in printing digital short-run labels. After researching a number of label printers, he settled on the iTech AXXIS Digital Label Printer from Allen Datagraph Systems, Inc., that features an Epson B-500DN inkjet print engine because it was bundled with Wasatch SoftRIP.

Digital Lollipop, an Australian digital label and sticker printing company founded by Tony Bogatie, has been producing quality products since they opened their doors more than a year ago. After working in the high-end flexo industry for eight years and watching technology advance, Tony saw the value in printing digital short-run labels. After researching a number of label printers, he settled on the iTech AXXIS Digital Label Printer from Allen Datagraph Systems, Inc., that features an Epson B-500DN inkjet print engine because it was bundled with Wasatch SoftRIP.

Label Production

Using Wasatch, Digital Lollipop can easily print many different label designs and layouts for their customers to choose from. This allows the customer to see a number of options before committing to one label. “It’s better than a digital proof because customers can see and feel the material,” says Bogatie. “They can even test it out on their products!”

If a product requires a sticky label, chances are good that Digital Lollipop is the company for the job. About half of their business is dedicated to printing labels for water bottles. The other half is dedicated to product labels, especially food, cosmetics, wine, and nutraceutical. With an average customer order of 500 labels, Digital Lollipop uses SoftRIP to produce high-quality labels quickly and efficiently.

Variable Data Printing

Variable Data Printing

Digital Lollipop uses SoftRIP’s Variable Data Printing Option (VDP) primarily for customizing their water bottle labels. Variable data on these labels typically includes names and serial numbers. “Thanks to SoftRIP’s Variable Data Printing Option, when a customer requires something customized, we never have problems fulfilling the request,” says Bogatie.

With SoftRIP’s VDP, Digital Lollipop can instantly create repeating values or sequential values, such as serial numbers, with the Auto-Data feature; customize variable data fields with fonts, barcodes, QR codes, Data Matrix codes, and a variety of sizing, color, and effect features; and automatically resize text and images with expand- or shrink-to-fit bounding box options. With so many customizable tools at their fingertips, Digital Lollipop can easily customize their workflow to fit nearly any label production process.

Color and Cost

Color and Cost

With Wasatch, producing quality color is easy. With the ability to use Correction Curves to make adjustments to image lightness, darkness, and specific color channels, Digital Lollipop can make color adjustments without ever leaving SoftRIP. “I’m not a color expert, but with SoftRIP I can easily get the color I want,” says Bogatie. “And, if I ever need help, I can count on Wasatch’s awesome technical support team.”

Digital Lollipop also uses SoftRIP’s Cost Estimator to estimate the cost of each job they print before they even start production. This feature makes it easy for them to perform an accurate calculation of ink usage, media costs, and extra processing charges. When calculations are complete, Digital Lollipop can export their results as Comma Delimited Text or directly to a print-friendly HTML web page.