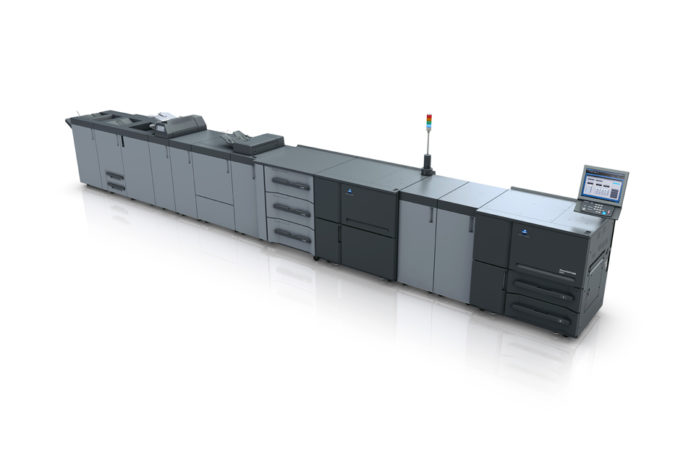

Konica Minolta Business Solutions U.S.A., Inc., (Konica Minolta), a leader in industrial and commercial printing and packaging solutions, today announced the release of its AccurioPress 6272P press, designed to help customers rethink monochrome print possibilities.

Commercial printers, print-for-pay services and central in-house printing operations are all major target markets for the fully configured digital production press, which replaces the bizhub PRESS 2250P.

Based on the highly successful single-engine AccurioPress 6136P, this flagship monochrome digital press utilizes dual-engine technology that enables printing more than 16,000 images per hour (ipm). Customers benefit from the AccurioPress 6272P’s best-in-class durability, reliability, productivity, efficiency and automation while optimizing their investment through a low total cost of ownership (TCO) compared to similar speed devices.

The AccurioPress 6272P prints 272 ipm duplex to meet tight print deadlines and supports a wide range of media, including coated and uncoated stock in weights from 40 gsm up to 350 gsm and ranging from 3.74-by-5.24 inches to 12.76-by-19.02 inches.

With a maximum input capacity of 18,000 sheets and a maximum output capacity of up to 18,600 sheets with three high-capacity stackers, the press delivers long, uninterrupted runs.

The tandem-engine combination, achieved through the tandem relay unit (TD-502), provides twice the speed and double the productivity in one integrated production process that offers superior image quality and a wide range of automated features.

The press uses LED printheads at 1,200-by-1,200 dpi with technology to ensure smaller fonts are crisp and halftones are smooth, producing stunning monochrome text and images.

As with the AccurioPress 6136P series, the 6272P uses CIE color space when converting color documents to black and white, creating richer gradations than conventional conversion.

Independent front-to-back alignment and a distortion-adjustment function ensure accurate duplex registration for book blocks, technical documents, and more.

The newly developed pass-through mode secures production in the rare case of a machine error, and the standard paper-cooling system enables all output to be processed immediately offline after printing.

Enhanced Efficiency by Automation

For printing companies looking to integrate their printing, and organizations that use digital printing to produce their own in-house publications and promotional materials, AccurioPro, Konica Minolta’s suite of digital solutions for professional printing, boosts speed and efficiency, expands capabilities and services, and reduces the need for operational manpower. Together these features streamline customers’ print jobs and help to boost their profitability.

A stacking unit and a wide variety of finishing options with an interface to third parties such as Plockmatic and GBC, enhance the 6272P’s speed and productivity for high-demand printing environments to create print products that stand out and create added value.

The press is also compatible with the IQ-501 for managing front-to-back registration and gradation. Additionally with the TD-502, customers can upgrade their existing AccurioPress 6136P and double its productivity to that of the AccurioPress 6272P.

“This launch represents another great example of how Konica Minolta supports its clients’ digital transformation through advanced automation, fewer human touchpoints and higher productivity with tangible effects that lead to increased, high-quality output with less waste,” said Dino Pagliarello, Senior Vice President, Product Management and Planning, Konica Minolta. “Combining features such as the AccurioPro Print Manager, TD-502 tandem relay unit and IQ-501 for registration ensure this system meets customer demands in high-volume printing environments.”

—Press Release