With the channel letter market saturated with low-cost modules, LED manufacturers are looking towards new applications to grow sales.

While visiting a wholesale sign shop about two years ago, I saw a four-by-twelve-foot, single-sided sign cabinet illuminated by someone sticking literally hundreds (432 to be exact) of channel letter LEDs onto the back of the sign.

I remember thinking two things:

(1.) There is an appetite by end-users and sign fabricators to use LEDs in larger wide format signs and sign cabinets; and

(2.) LED manufacturers need to develop systems that are easier to install.

Today there are some excellent LED solutions designed specifically for larger single- and double-sided cabinets (both new construction and retrofit).

Basically LED innovations for wide area signage can be broken down into three product categories: backlit modules with lateral light spread, return mount or side-illuminated systems, and cabinet products.

Each manufacturer has their own twist on these systems—each with different features, benefits, and cost points. Let’s take a look:

Backlit modules with lateral light spread are particularly good for larger, lower profile signs. They’re either designed with a special “batwing”-type optic that forces more light away from the face and towards the sides or return of the sign, or the LEDs are mounted in a way to force light laterally versus traditional lambertian 120o SMD LEDs.

While some manufacturers offer lower output modules for ultra-thin channel letters, as a general rule, these systems offer no real benefit for single-stroke, standard-depth channel letters (since the light is just wasted and never gets to the sign face).

The real benefit for these systems is in thin multi-stroke sign applications.

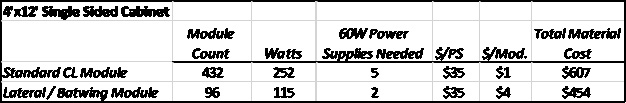

Referring back to my initial four-by-twelve-foot, four-inch deep single-sided sign example, no one wants to peel and stick hundreds of modules down a sign back. With a standard channel letter module, you’d have to use a three-module-per-foot system and place them on four-inch centers.

With a lateral spread/batwing module, you can use two modules per foot and, depending on the manufacturer, place the modules on nine- to twelve-inch centers. (Note: Table 1 shows an actual comparison.) Table 1

Table 1

My point is that even though one module costs four-times as much, the actual cost of the LED system to build the sign is 25 percent less. (And that doesn’t include the labor savings of having to install 75 percent less product and power supplies!)

If the sign is deeper (>8 inches), just like the channel letters, the benefits begin to go away, since you can now place a standard module with a 120o lambertian optic on wide centers and get adequate coverage. However wide beam angle LEDs with lateral optics are the best bet for shallower, multi-stroke channel letters and cabinets.

Side-mount and edge-lit modules are less utilized, but they work really well in specific applications.

For larger cabinets, some manufacturers offer systems that have a focusing optic. These systems work in the opposite way of a batwing optic. They actually focus the light emitted from the LED in such a way that the light is narrow, and the module is designed to mount on the side or return of the sign.

GE Tetra EdgeStrip product contains a special OptiLens with a 10x80o viewing angle that puts out up to 410 LM per module. EdgeStrip can evenly light signs up to five feet in width and can work in sign depths as thin as three inches.

SloanLED has similar products: Sloan PosterBox and PosterBox Slim are 550 LM and 120 LM per module, respectively. PosterBox utilizes a unique FlareShield technology to eliminate hot spots near the edge of the sign.

It should be noted that, since all of these products utilize specific optics, they work better in certain sign depths and sizes than others and should be tested in the shop prior to installation.

I’ve found that they’re great in double-sided cloud- and blade-type signs. Most of these products work best when there are more “busy” graphics on the face, as these signs are more forgiving of variances in illumination across the sign face.

For wide format, edge-lit indoor signs, some manufacturers have developed thin high-output LED modules that are designed specifically to work with edge lit acrylics, such as Acrylite® LED (Endlighten) from Evonik Cyro, LLC. These plastic sheets utilize embedded particles that spread the light laterally. This removes the need for patterning or laser-etching the material and allows the sign manufacturer to cut them down to any size.

The Acrylite LED (Endlighten) material comes in several grades and thickness options depending upon the size of the panel to be illuminated (Table 2). Principal LED’s Spec. Edge is a plug-and-play LED strip that’s designed specifically to work with these types of plastics and can evenly light up to a four-by-eight-inch sheet of Acrylite LED (Endlighten) from each edge.

Table 2

Table 2

SignComp and other aluminum extruders also sell frame kits that work well with these edge-lit systems. These components allow a sign manufacturer to custom-build their own edge-lit light boxes without buying specialized equipment or having to order from a third party.

Cabinet products are the biggest growth area for LEDs in the sign industry. There are a number of systems now available that meet or exceed the brightness of traditional HO-T12 lamps at prices.

“Just as LEDs have virtually replaced neon in new sign construction, they will ultimately do the same with fluorescent lamps. Accessories have made both retrofits and new sign construction with LEDs easier and faster to install than fluorescent lamps systems. Any financial advantage an inexpensive fluorescent lamp has over LEDs is erased in one or two lamp changes,” says Bob Magnus, vice president of Sales & Marketing at Ventex.

Each manufacturer has its own system with slightly different features. Ventex sells a Snap Stick that’s a custom extrusion designed to be assembled with their existing Venbrite LED modules. This allows the sign maker to repurpose the same modules in a cabinet as in wide format channel letters.

USLED’s Tandem2 system for single- and double-sided cabinets has a special interlocking rail system that contains specifically designed LED modules, which can be easily adjusted up and down the rail. Principal LED (Qwik Stik) and Permlight (Linearray) have systems that come pre-assembled in specific lamp sizes and can fit directly into a T-12 socket or with separate mounting hardware for new signs.

Just like LED modules with lateral optics, these systems reduce the need to peel-and-stick hundreds of LED modules. They have also have been designed to work in double-sided cabinets without the need to add a separate baffle during fabrication.

There’s no question that LEDs will continue to expand their market reach beyond the traditional channel letter over the next few years.

“We’re transitioning 100 percent of our single and double-sided cabinet signs to LEDs, because they’re the fastest-growing segment of our business,” says Ben Ziglin, president & CEO of Ziglin Signs in Washington, Missouri.

Innovation has come in the way of specialized materials and optics to put light where it needs to be on the sign face in order to reduce fabrication times and maximize energy savings. Looking into these options can help sign makers save time and money and expand their product offerings to end-users.

By Blake S. Vincent, a managing partner at Principal LED of San Angelo, Texas.

Photos: