One of the first things I hear from shop owners when they hire me to help them turn their companies around is how proud they are of cross-training their work force and how they have sound production scheduling practices. I ask myself, then why are they having production issues leading to lack of profit, poor cash flow, late delivery dates, excessive overtime, and rework?

One of the first things I hear from shop owners when they hire me to help them turn their companies around is how proud they are of cross-training their work force and how they have sound production scheduling practices. I ask myself, then why are they having production issues leading to lack of profit, poor cash flow, late delivery dates, excessive overtime, and rework?

Granted cross-training has its advantages, but it also has disadvantages if the only time you capitalize on effectively utilizing those resources is when the need arises to cover the bases when someone is on vacation or sick. The key is “functional” cross-training.

That aside for the moment, more than likely there are additional forces pushing against your ability to get all you can from your workforce. One is “bad” multitasking in scheduling task assignments.

The biggest mistake made among shop managers is not realizing the power of correctly balancing shop talent to maximize throughput. Underutilized capacity represents a big opportunity to improve bottom line profits without investments in additional manpower.

What if you could boost future capacity by proactively cross-training and scheduling production task assignments differently to achieve more predictable results with little or no out-of-pocket expense? Read on to learn how.

The goal is having the right worker doing the right task at the right time!

This sounds like a simple enough concept, right? But how do you figure out where and when you will have gaps down the road in your production line and what type of training will help your team fill those gaps efficiently?

For starters, I suggest reading The Goal by Eliyahu Goldratt to learn about the Theory of Constraints (TOC). This will open the door into new insights on how to improve your shop performance and achieve bottom line results.

In this article, I’ll touch base on the TOC concept of multitasking and how it plays a big role in achieving higher levels of production efficiency, and then I’ll move onto cross-training to maximize throughput.

First let’s look at the definitions of TOC versus human multitasking (which most of you do now) and how they relate to achieving higher levels of output.

TOC Multitasking involves stopping work on a task before it is completed in order to start work. Multitasking itself is neither bad nor good. Bad multitasking occurs when switching tasks does not help any project finish earlier.

For example, in a multi-job shop, it is common for resources to be required to switch between tasks on various jobs (or within the same job) in order to show progress. Such multitasking usually extends the duration of all jobs and, therefore, is bad multitasking.

If, however, a resource is forced to stop a task on one job in order to complete a task that is delaying the critical chain or the most penetrating chain on another job (thereby helping that job to finish earlier), it is usually considered good multitasking.

Human Multitasking is an apparent human ability to perform more than one task or activity at the same time. An example of multitasking is taking phone calls while typing an email and reading a book.

Multitasking can result in time wasted due to human context switching and apparently causing more errors due to insufficient attention.

Takeaway #1

Good multitasking allows projects to finish in priority sequence without delay. There are no stops and starts (unless intended), and profits are protected. Human multitasking has the undesirable effect of increased costs due to interruptions and potential rework errors.

According to Gloria Mark, who studies digital distraction at the University of California, Irvine, it takes an average of about 25 minutes (23 minutes and 15 seconds, to be exact) to return to the original task after an interruption. In other words, that “30 seconds to check Twitter” isn’t just 30 seconds down the drain. It’s 25 minutes and 30 seconds.

Multiple studies confirm distractions don’t just eat up time during the distraction; they derail your mental progress for up to a half-hour afterward (and that’s assuming another distraction doesn’t show up in that half hour). And all these distractions not only hurt productivity, but they also have negative emotional effects.

This is just the tip of the iceberg. What about the person interrupting and the person before him or her they were probably distracting as well? Regardless of the chain of events, let’s dig a little deeper to find out how much it’s really costing.

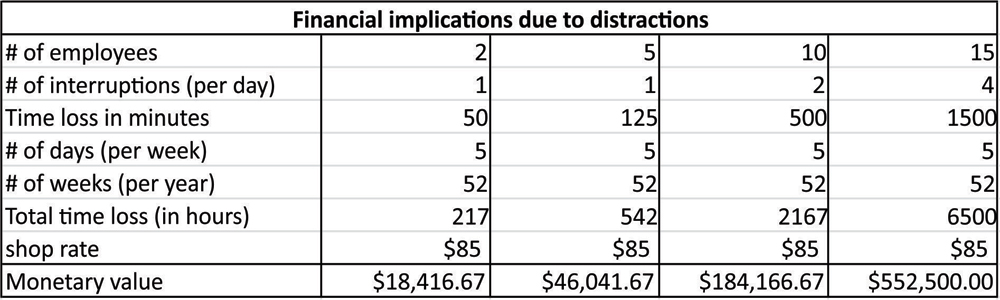

Make an estimate on how many distractions occur during an average workday, week, and year. Now take that number and multiply it by 25. That’s how many minutes of concentration you’re losing. Now multiply by the number of workers and then multiply by your shop rate (see Chart 1).

It’s pretty obvious how big a deal this is. That money and time represents capacity lost forever and dollars your bottom-line won’t benefit from.

Takeaway #2

Minimize distractions that cause production interruptions, stops, and restarts as much as possible.

I’ll bet you’re wondering what this all has to do with functional cross-training to maximize throughput. Well it will all make sense as you read on.

In functional cross-training, the operative words are “functional” and “throughput.” “Functional” means adding capability and exploiting it, and “throughput” means getting more work out the door.

To maximize throughput, managers need to get the most out of their system before they can get the most out of their team. Then it can be determined what specific cross-training will facilitate the ability to do even more work.

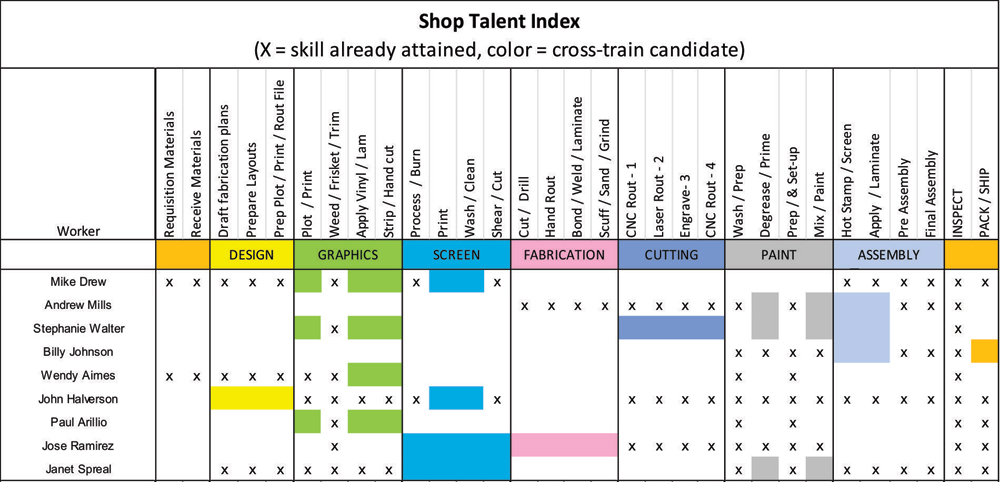

Assuming you’re there now and ready to start training, you’ll need to determine the who’s and what’s. It’s as easy as plotting out a chart (see Chart 2) that lists the task work required to produce your products (listed across the top), with your workers (listed down the side), and marking an X to identify what they are already trained to do if assigned. Then find the gaps and color the cells representing areas to consider for training in each department!

Takeaway #3

Use functional cross-training to increase your shop’s capacity to do more work!

To wrap things up, what I’ve described to you thus far are fundamental concepts. The work in earnest must be taken on by a dedicated leadership team with experience.

Business managers that are not receptive to change will have a hard time breaking away from practiced norms. In their case, the tutelage is interesting but not a game changer.

For those of you who want to make lots of money and compete at the highest level, three great ways to unlocking employee talents are: good multitasking, no distractions, and functional cross-training.