You know that dependable quality is one of your most important competitive strategic tools. Whether small or large, a manufacturing organization needs to provide customers with great products and services exactly as promised each and every time.

Quality control (a.k.a., process control) is a key component in this formula. When organizations fail to strive for process excellence, it eventually results in some form of rework. Rework leads to the loss of profits and, in some cases (worse yet), the loss of a customer.

You know how important this issue is, but let’s do a quick review of the real costs that affect your bottom line before we jump to ways to prevent costly rework.

Suppose, for example, that your sign company has a (year-end) after-tax profit margin of 9 percent; then we can assume the average profit margin on jobs is also 9 percent. This means (on average) that every project with a selling price of $10,000 has a profit of $900 (9 percent of the selling price).

Now suppose that, just prior to installation, a problem is discovered that requires this job to be reworked to the tune of an additional $1,500 worth of labor and materials. This assumes that the company has sufficient capacity to redo the job (without negatively affecting other jobs in progress) and that there are still available production days left in the schedule to meet the original client promise date.

The selling price is still $10,000, but the job now becomes a liability (costs you money) instead of an asset (makes you money). The impact of the extra work is you’re out $900 profit revenue and $600 from your bank account = $1,500. This would send most owners reeling; but it’s bigger than that.

To make the money lost you can’t just say, “We’ll make it up on the next job!” Because the truth is, unless you can somehow magically increase your efficiency on the next same-size order by two-fold (or 18 percent), you’ll now need to sell $16,700 of new business ($1,500/.09) to get you back to square one—if you don’t mess up that one too!

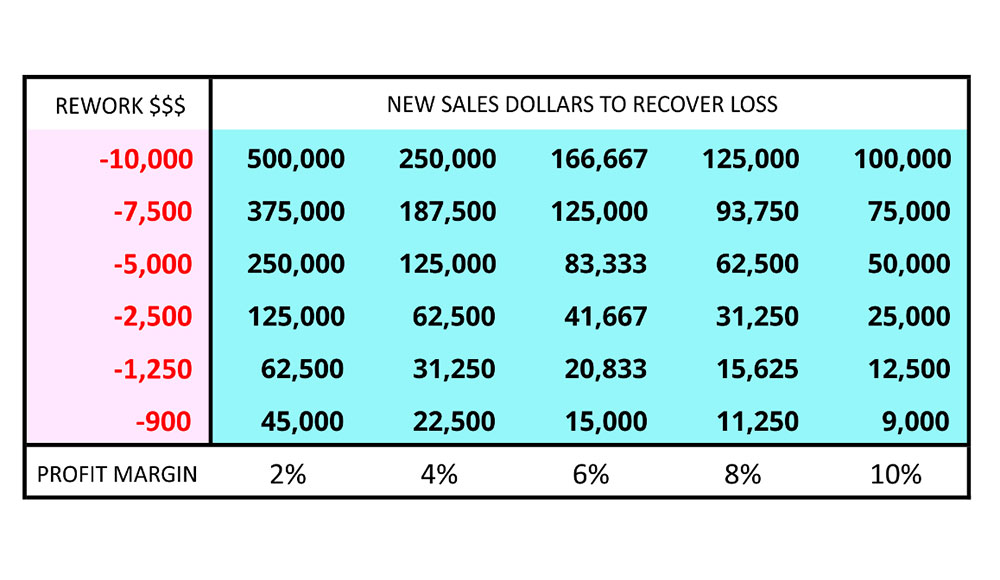

As you can see from the chart above, the healthier a company is, the easier it is to recover. Firms that are doing well (10 percent) versus breaking even (2 percent) have a 5X competitive advantage!

As you can see from the chart above, the healthier a company is, the easier it is to recover. Firms that are doing well (10 percent) versus breaking even (2 percent) have a 5X competitive advantage!

The repercussions are even greater! There are indirect impacts such as the cost of borrowing money, stops and restarts, management rescheduling, material handling, hits on employee morale, and a general level of frustration throughout the company—not to mention lost time.

It’s a vicious loop of catch-up that you can never break away from unless you make significant changes in the way that you operate your business.

The point: Rework is a profit drain that most companies can ill-afford when replacement profits are hard to come by. Yet many owners and their managers don’t pay enough attention to the “root causes” of reworking and fixing underlying conditions because they’re too busy fighting fires or it’s so common that they just don’t realize it.

It’s my opinion that the fastest, most cost-effective way to increase your bottom line and keep cash in the bank is to eliminate waste and stop doing things more than once!

The real tragedy here is that most of the actions (or inactions) that create the need for rework are preventable. And it’s not only production that plays a role in the prevention; sales, design, and project management are important players too.

Here are five best practices that will help you prevent rework:

1. Proper Production Documentation

In a build-to-order (job shop) environment, typically the project was estimated and sold based on conceptual drawings or renderings done by a designer or architect. These are certainly enough to get the job in the door but rarely good enough to support the successful completion of a project delivered on time and under budget.

Without a rock-solid production documentation package, the job should not be released to the shop floor to start fabrication unless you want a total disaster and enjoy mopping things up along the way.

Proper manufacturing documentation includes scaled construction shop drawings (approved by engineering), concise written specifications, clearly stated scope of work and detailed build estimates, customer-approved designs, color callouts, job site photos, survey measurements, etc.

Pro tip: Execute a disciplined order acceptance process using checklists as quality control “Gate Keepers.” This is a great way to organize and streamline information flow.

2. Thorough Planning

Many shops are eager to get started, so they release jobs (to the shop floor) before there is sufficient information to complete the work or see idle machines or workers waiting for work. But don’t be fooled.

Early starts are bad. Don’t begin before you’re ready!

“Ready” means that you’ve received and verified everything required to release the shop order. This planning includes fabrication and engineering details, release sequencing, material requisitioning, batch planning, material yields (cut plans), resource allocation (team and vendor selection), and WIP scheduling.

Pro tip: Implement a full kitting policy that refers to job travelers being 100 percent complete, accurate, and timely. If it’s not a “full kit,” it’s to be considered still in planning and not approved for fabrication!

3. Proactive Supply Chain Management

3. Proactive Supply Chain Management

Now that plans and specifications have been vetted, the shop should be readied to receive the handoff. This includes team meetings to identify priorities, review assignments, time targets, critical benchmarks, and any other activity relevant to successfully completing the build without interruption.

Additionally the shop floor and work centers should be clean and free from interference/obstructions. All machines are in working order and tools, supplies, and materials have been received, checked, and queued up or “stagged” in the appropriate places.

Pro tip: Learn Kanban strategies to safeguard against supply chain constraints.

4. Maximize Manufacturing Flow

The project is starting off in great shape. You’ve done everything you can to set yourself up for a big win. The only thing that will prevent you from being run over by the bus is if you take your eye off the ball.

Even in the best-laid plans, workers are pressed by upper management to show progress, which leads to error. All it takes is one wrong cut, wrong weld, poor LED connection, rushed paint prep, incorrect color mix, etc., to bring catastrophe.

The worst thing that can happen is to find project deficiencies just before it’s about to leave your building.

To prevent this, quality control as you go—meaning QC is happening between the handoffs from one task operation to the next. The sooner you catch errors then the less impact on the whole system.

One great way to maximize product flow and drive out confusion is to keep parts and subassemblies well organized on rolling flow racks and labeled with staging tags. Staging tags serve as identifiers and a quality control tool. Make it a policy that require signoffs at the end of each stage of production.

You can even classify jobs as “Control Model 1” or “Control Model 2.” CM1 is a one-signature process (tolerances are not that particular), and the technician can self QC and move along. CM2 is a two-signature process (tolerances are extreme, and fit and finish are of the upmost concern), where a second qualified person inspects and approves quality before the product moves to the next work center.

Pro tip: Learn Batch Production versus One-Piece Flow principles to improve lead time.

5. Monitor and Report Early and Often

One of the most important management activities that should be happening during the entire project is to monitor work in progress (WIP) and document activity and report to stakeholders how things are progressing. This prevents lots of “people” interruptions throughout the day—especially from owners and salesmen walking to the production floor asking, “How’s my project job going?”

If things get off track (which they will), you’ll have a system to give and get information that enables you to implement counter measures before significant damage can happen. A good reporting system keeps everybody informed at all stages of the process—especially customers!

Pro tip: Implement daily job status reporting (JSR). Make it the responsibility of one person to manage updates and broadcast in PDF format to all stakeholders. Basic info should be categorized into seven sections: (1.) New job intake, (2.) Planning, (3.) WIP Release Queue, (4.) In-Production, (5.) Installation/Delivery, (6.) Complete-Ready to Invoice, and (7.) Job Hold. Prioritize by customer promise dates.

In closing, I hope these best practices will benefit your organization as they have for me and my clients. Remember it’s all about proactively controlling the project environment to prevent as many things as you can from going wrong.

Problems do occur, and rework is going to happen. But when you continuously focus on process improvement and do everything you can to drive out waste, you automatically drive-up quality and everything else with it—profits, cash flow, employee morale, customer loyalty, referrals and more.

As the saying goes: “Happy customer, happy life!”

As the saying goes: “Happy customer, happy life!”

John Hackley brings over thirty-five years of experience in build-to-order sign manufacturing. He is the owner and consultant for Oculus Business Solutions and promotes lean production philosophy and strategies to help your business grow and profit.