Vycom, a market-leading manufacturer of highly innovative plastic sheet products, has seen an uptick in demand for its Vintec® Clear PVC sheets, for use as a barrier material in retail, hospitality, education, and consumer-facing environments where safeguards are required. Vintec Clear is part of the Vycom Corrtec™ chemical- and corrosion-resistant family of materials, designed to meet requirements in industrial applications.

Familiar Print and Cut Process

Vintec Clear PVC sheets offer superior ink adhesion for digital and screen printing processes and can be thermoformed and cut. They can be used as a stand-alone barrier or as part of a system utilizing other Vycom products including Celtec® expanded or solid PVC sheets. The slight blue tint provides an immediately recognizable boundary that reduces unintentional contact because of its visibility.

Chemical Resistant for Longevity

The improved chemical resistance of this product line enables it to hold up better than traditional clear plastic materials against commonly used cleaning products and disinfectants. While cleaning solutions are effective in sanitizing plastic surfaces, some chemicals will cause polycarbonate and acrylic materials to haze, stress-crack and degrade over time. Vintec Clear PVC sheets are designed to stand up to these products for reliable, longer term use.

From Portable Desk Shields to Panels that Create Separation Without Isolation

Here are some examples of recent uses of Vintec Clear sheets:

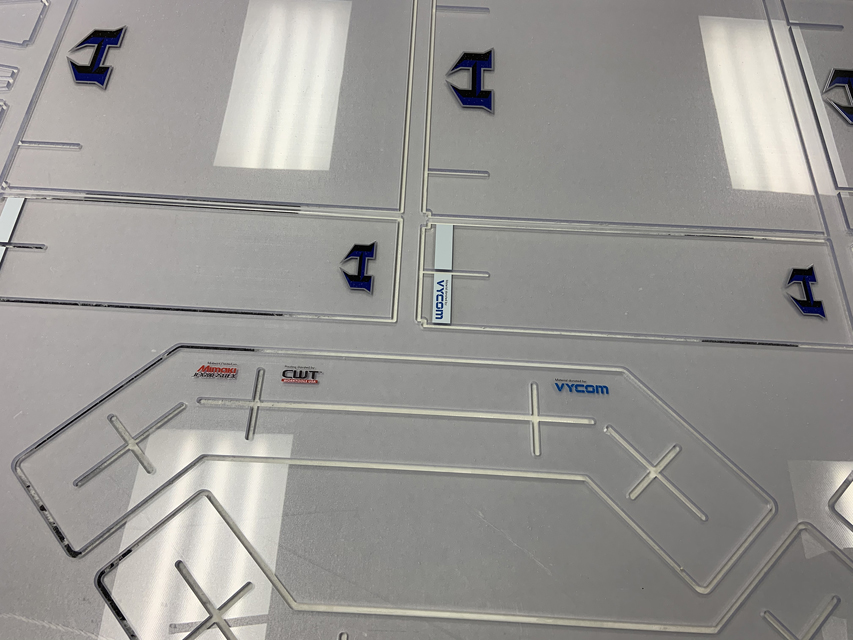

Vycom, Mimaki USA, and CWT Worktools USA recently came together to create portable custom barriers for use by the debate team from Hebron High School in Carrolton, Texas. Vintec Clear 1/4-inch sheets were printed on the Mimaki JFX200-2513EX flatbed printer using LUS-120 inks and a 6-layer print technique. The material was cut on a CWT Apex digital flatbed cutter to create desk shields that can be quickly assembled and disassembled for easy portability during competitions.

Strandz Salon in Newington, Connecticut, used Vintec Clear panels to create barriers that met the requirements for reopening protocols in the state. The panels were easily fabricated using basic tools including a circular saw, drill, and a deburring tool, and installed using steel chains and S-hooks.

“We have panels in the reception area, at the check-out desk, between the stylist stations, and between the shampoo stations,” said Kelly D’Anna, owner of Strandz Salon. “While I can see through the panels, the slight blue tint means that anyone in the salon intuitively knows where the panels are, and won’t accidentally bump into one. Our customers also like the additional privacy afforded by the panels.”

—Press Release