Most of us can identify with this question, especially those of us that have taken long road trips with our parents or kids. My three sisters and I asked this question all the time. At one point, my dad, completely sick of it, came up with a great conversation stopper –“Well, actually, we’ve passed it. I’m not sure where we’re going, but we’ll know when we get there.” WOW, what do you say to that?

In thinking about the events over the past few months, how many times have we asked ourselves, or others, a similar question – when will we get to the new normal? How will we know? Good questions and not a lot of good answers, unfortunately, especially for those of us in the business world or those owning a business.

My own thought is that we are on a journey, a continuous one, to reach a destination of sorts. We need to be looking at our businesses as on a journey as well, right now. What do I mean by this? Let me explain.

I spent 20 years as a turnaround professional in the printing industry. My job was to go into failing companies, $1MM-$50MM in size and losing money, fix them, and make them profitable, viable, and sustainable entities. Each one had different issues, customers, and products, but in the end, the process was the same – a continuous process or journey from point X to Y. By all accounts, each of our businesses needs to be on this journey today to become more efficient and profitable in the long run. And why the need for efficiency:

- Very short-run printing will be the name of the game. This can be costly if you are not prepared with staffing, processes, and a highly focused customer orientation.

- An estimated 30% of the printing companies are expected to go out of business.

- A surplus of printing equipment will result with the equipment available at low cost.

- There will likely be a reduced number of customers, i.e. retail accounts and locations. Demand will be shrinking faster than supply.

- An accelerated consolidation of print solution providers means fewer, very competitive, and highly aggressive companies in the marketplace.

So, what can you do to make yourself more efficient and competitive? Here is a list of things that I used religiously to make each of my companies successful along with some examples:

First up, product line rationalization. Do you know which of your products is making money and which are losing money? Know this and make a rational decision to continue producing them – maybe they are part of a larger sale to a large customer which, overall, is profitable – or discontinue producing them.

Second and one of the most difficult – rationalizing your customers. Which accounts are making money, and which are not? It’s uncomfortable, awful, but has to be done. Example: During my turnaround tenure with one of the Pitney-Bowes companies, we took a hard look at each of our accounts from a profitability standpoint. In the case of Federated Department Stores, a name with a lot of cachet, a great customer, and one that was ideal to have on our reference list, we found they accounted for 60% of the orders and 5% of the revenue. We even had a whole separate production area and flow for them along with significant labor to support the business. It became clear that this was not a sustainable business and, as hard as it was, we had to part ways or have them accept a 250% price increase so we could make money. They opted to leave us. We adjusted our production, and within 2 months, we were on our way to becoming cash rich. There is also a point of strategy here: If you’re giving up some business that is not profitable, hope that one of your competitors get it.

Third, reduce cycle time. This is one of the fastest ways to pick up business and maintain higher margins if you manage it well and have 98%+ on-time performance. This also brings up another point of strategy that I love and works very well. I learned it from 3M. Not only would we work on reducing our turn times by one day, we also made the plans to reduce them by 2 days. Why? We would roll out the 1-day reduction, increase price and margins. Competition would see what was happening and inevitably figure out how to do it, too. This is the point where you drop your turnaround a second time, keep the premium pricing while working on the next reduction, and leave the competition in the dust. You’re now one step ahead, unless they try to make a giant leap (which I’ve not seen work yet.)

Fourth, with everything in the process of being shutdown again, remote monitoring of your operation via mobile apps along with automated maintenance will give you a leg up to keep your production running smooth.

Fifth, drive quality and production improvement through the use of LEAN, Six Sigma, 5 Why’s, etc. Not only will customers love the high quality, but you’ll love the potentially higher margins that you get from higher prices and/or improved efficiencies in production. For more information, I suggest reading Michael Porter’s Competitive Strategy or Eli Goldratt’s The Goal. These are excellent books to help you determine where you fit and how to get to where you want to go.

There’s a lot of work here, lots of work, but well worth it in the long run. There are also software tools out there that can help you along. HP’s PrintOS cloud-based system is one such tool that is both open and secure while working with the large format printer portfolio AND it’s free to use. Not all printers come with the entire suite. Each printer type is provided with the modules that make the most sense for it.

Here is a quick overview of some of the modules and what each can do:

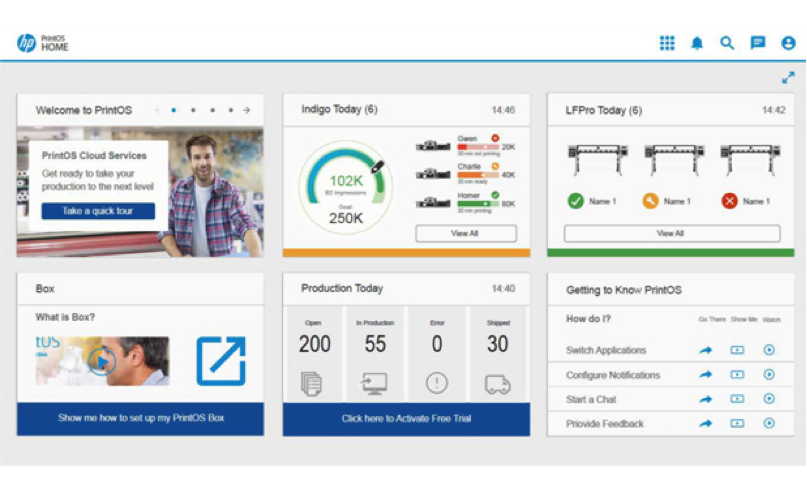

1) The PrintOS Dashboard

This is a welcome dashboard, customized to the user needs, that pulls together data from multiple applications to provide an integrated view of the operation. One view captures everything you need to know.

2) Print Beat

One of the modules that is available with specific printers and can be accessed via email, the web, or HP PrintOS Mobile App. There are four key elements to this module:

a) View near real-time and historical data for full transparency and attention.

b) KPI (key performance indicators) enable continuous operational improvement.

c) Monitor and control status anytime, anywhere from a PC or a smartphone, either iOS or AndroidTM.

d) Operational Excellence. Benchmark printer performance for continuous improvement.

3) PrintOS Mobile App

Ideal for lockdowns or anytime you need to be away from the printer.

a) Gain control with near real-time status.

b) Understand trends and make quick, data-driven decisions based on insights and historical reports.

c) Get full production monitoring of printers and jobs in near real-time status, accessible anytime and anywhere.

d) Drive continuous improvement as KPI’s provide in-depth visibility into production operations.

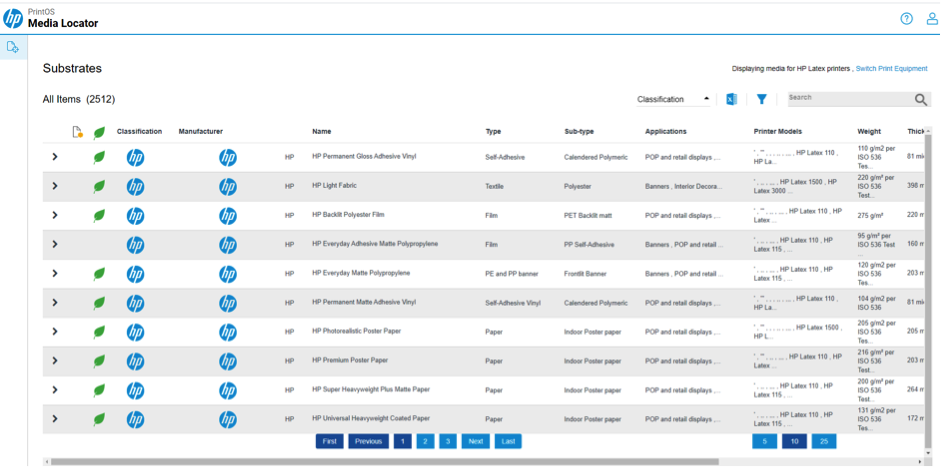

4) Media Locator

Easily track down and locate the right certified media for your jobs across geography, applications, media types, etc. Key benefits include:

a) Accuracy and color consistency when you use certified media together with pre-defined sets of parameters for optimal results and smooth production.

b) Productivity optimization minimizing human errors and improving utilization by automatically downloading substrate parameters, including media fingerprints, directly to the printer.

c) Cost Savings in setup time and media usage for color calibrations.

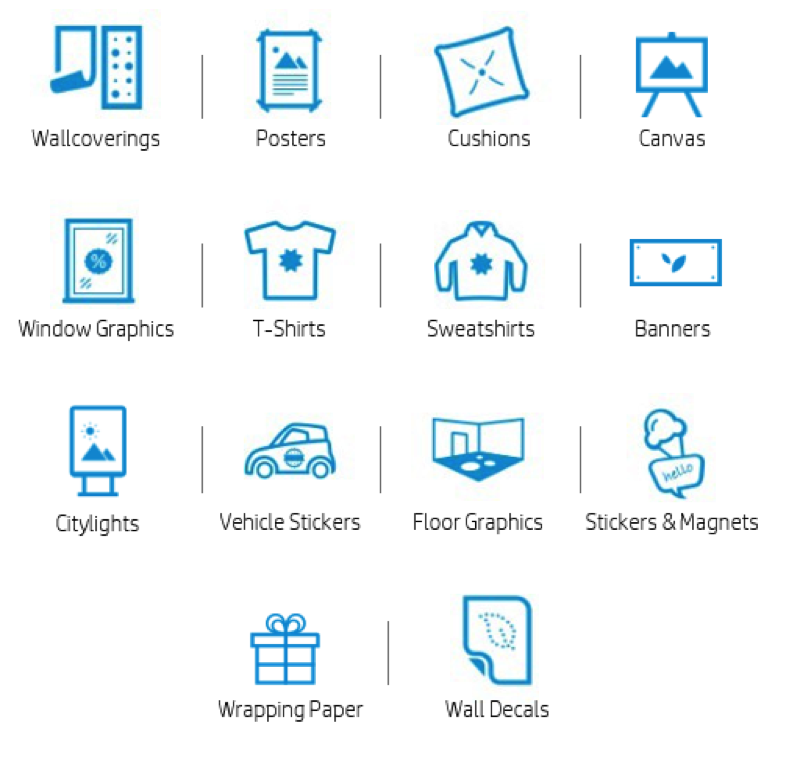

5) PrintOS Applications Center

With this tool, you have access to a full web-to-print solution where designs can be shared securely with existing or new customers. In addition, you can power up a web-to-print business by helping customers easily create a variety of applications on your own website. Application support is included for:

UPDATE!! – APPLICATIONS CENTER NOW HAS TEMPLATES FOR COVID-RELATED PPE SUCH AS MASKS ALONG WITH COVID-RELATED SIGNAGE. CHECK IT OUT NOW!

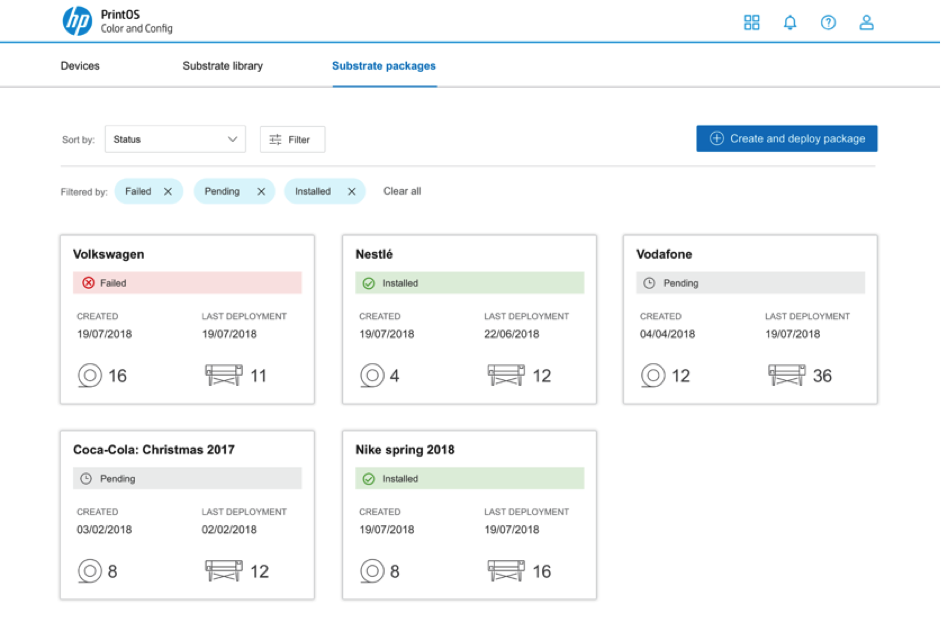

6) Configuration Center

Color control made simple for in-printer color consistency along with color consistency across a fleet of printers. Given the fleet size and global footprint of printers (25 countries) in two of my companies, this is a module I wish I had at the time as it provides:

a) Remote access to all profiles from My Printers, HP Media Locator, and even from My Resellers, all in one location.

b) The possibility to create packages of profiles and deploy them to compatible printers both remotely and across sites.

c) The ability to achieve color consistency of split jobs between printers of the same family. It also makes installation of new printers to the fleet much easier.

While there are several more modules, these seem to be the most relevant to the large format user. For more information on PrintOS and additional modules, go to www.printos.com.

At this point and with all the information provided, I would ask each of you to consider where you are in the journey – are you starting, are you somewhere in between, are you ready for what is to come? What I’ve provided is only the tip of the iceberg and there are lots of books, videos, and HP webinars and academies that can help you figure out where you are going. How will you know when you are getting there? Sales and income growth and, more importantly, the smiles and satisfaction with your ever-growing customer base and employees. There is nothing like it. You might think you’ve arrived at the destination, but it’s just the start of the next phase of the continuous journey to improvement and surviving in the new normal.

For more information on HP PrintOS or attending HP events, contact your local HP sales manager, HP reseller, visit us at www.hpvirtualbooth.com, or call us at (877) 215-8584.