Electronics For Imaging, Inc. (EFI™), reports it has completed a life cycle assessment (LCA) of Nozomi single-pass digital print technology in partnership with award-winning sustainability consulting firm Clean Agency. Through this initiative, Clean Agency also developed an LCA tool that EFI customers and their customers—such as brands, retailers, and 3PLs—can use to analyze their CO2 equivalent (CO2e) emissions as part of their overall packaging extended producer responsibility (EPR): the environmental impact of their products, even after their useful life has ended.

According to the LCA, printing corrugated materials on an EFI Nozomi digital press reduces global warming potential (GWP) by approximately 50 percent when compared to analog printing technologies.

“No printing plates, less energy, less waste, and just-in-time (JIT) manufacturing all contribute to CO2e reductions for corrugated printing on EFI’s Nozomi digital press,” says Seri McClendon, CEO of Clean Agency. “Packaging is a major contributor to Scope 3 emissions, so we not only partnered with EFI to conduct the LCA but also to build a calculator that enables users to quantify related kilograms of CO2e for specific packaging printing volumes and applications.”

Scope 3 emissions refer to indirect emissions that occur in the value chain of an organization, including both upstream and downstream activities, and represent a significant portion of a company’s carbon footprint.

For prospective customers, brands, and retailers, the LCA tool can calculate the CO2e of a given print job on Nozomi technology, as well as project and compare what the same job would generate on other printing technologies, including flexography, offset litho, and digital pre-print.

Demonstrating reduced footprint of packaging production is a business advantage in a time where Scope 3 emissions are a critical consideration in comprehensive sustainability strategies.

In addition, these sustainable advantages of digital print also enhance productivity and business outcomes—such as through the elimination of plates, reduction of changeover waste, lowered energy, waste disposal costs, and more.

“We are pleased with the results of the LCA and are pursuing independent third-party verification of the findings for additional validation, which we anticipate coming in April,” said Evandro Matteucci, EFI’s VP/GM of Building Materials and Packaging. “It’s an iterative process, and we will continue testing and proving the LCA with our customers going forward.

“The insights substantiate digital print’s positive impact on sustainability as well as our overall commitment to our own and our customers’ sustainability goals. The LCA tool is a key value proposition for all users, as the ability to demonstrate clear footprint reductions not only aligns with ethical values but also enhances brand reputation and competitiveness in the market.”

EFI customers have already begun to leverage the new LCA tool with positive reception. UK-based leading corrugator and packaging provider Caps Cases completed its own LCA analysis. Because of their Nozomi investment in EFI digital printing, in 2023, Caps Cases avoided approximately 300,000 kilograms of CO2e when compared to analog methods.

“EFI’s investment in this LCA calculator will help us quantify and communicate Scope 3 emission reductions to the brands and retailers we serve,” said Trevor Bissett, CEO of Caps Cases. “In fact, according to our calculations, our largest customer avoided 60,000 kilograms of CO2e by switching to Nozomi digitally printed packaging in 2023. To have the ability to communicate this calculation and its impact provides a strong testimonial for our digital print solutions and indicates our commitment to being a sustainable manufacturer.”

The LCA tool is the latest development in the history of EFI Nozomi technology pushing the corrugated printing industry in a significantly more sustainable direction.

Eliminating expenses and a great number of steps associated with printing plates, printing, and lamination in traditional analog production, single-pass digital inkjet printing for corrugated packaging contributes to a circular economy thanks to a reduction of overproduction, waste, and storage costs, LED curing that reduces power consumption, and the elimination of water to wash presses and inks.

EFI Nozomi LED inks emit virtually no volatile organic compounds (VOCs), meeting the GREENGUARD Gold standard and requiring no vapor recovery. Nozomi technology is the only single-pass digital inkjet offering that is certified for Old Corrugated Containers (OCC) recyclability, and repulpability by the Western Michigan University Recycling, Paper, and Coating Pilot Plant.

ozomi printers also are recognized as energy efficient based on the ISO 20690 energy standard as awarded by Fogra Research Institute for Media Technologies.

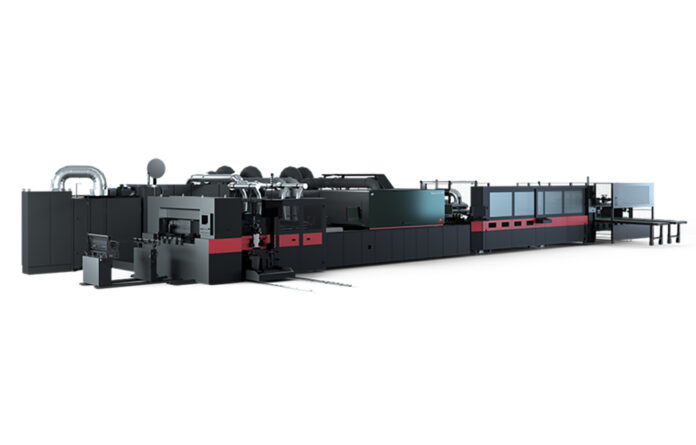

With models for traditional corrugators and the sign and display market, EFI Nozomi printers boast a robust design for heavy industrial use, high reliability, and high productivity.

—Press Release