E. L. Hatton Sales Co. will introduce its new Banner Ups BravoBanner® System, a fully automated banner finishing system, at SGIA 2015 in Atlanta, November 4-6.

Banner Ups’ pressure-sensitive adhesive tabs and tapes allow banner producers to make high-strength reinforced banners quickly in-house without sewing, welding, or grommeting. The new BravoBanner system automates that process, making the Banner Ups system economical for high-volume banner production.

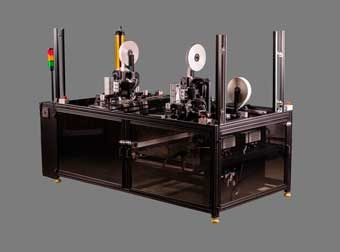

The BravoBanner system automatically applies Banner Ups BravoTabs and BravoTape with a few keystrokes. Dual heads apply tabs and tape simultaneously along the top and bottom edge of the banner and are easily adjustable to accommodate variable widths. With hem taping speeds of up to 80 feet per minute, the BravoBanner system can finish about 100 banners per hour with a single operator, dramatically reducing labor costs. The machine also punches rope holes, and will be available with an optional grommet module. The system’s efficient mechanical footprint (less than 50 sf – about the size of a large office desk) and low electricity requirements save on precious floor space and power when compared to sewing or welding systems.

“The BravoBanner System automates the banner finishing process for high volume banner production,” explained company president, Rick Hatton, “Surprisingly, as mature as the banner business is, that has never been done in the past. This innovation can shift the entire model for large-scale banner production efficiency and cost.” The BravoBanner® system will be on display at SGIA 2015, Atlanta, in the company’s booth #1417.

E. L Hatton Sales Co. designs and produces Banner Ups Adhesive Grommet Tabs, PowerTabs, and PowerTape products which are used to fabricate super-strong banners instantly without sewing or grommeting.