Canon U.S.A., Inc., a leader in digital imaging solutions, announces the launch of the Océ Arizona 6100 Series, an entirely new printer platform designed for sign and display print service providers who produce approximately 325,000 square feet of printed rigid media per year.

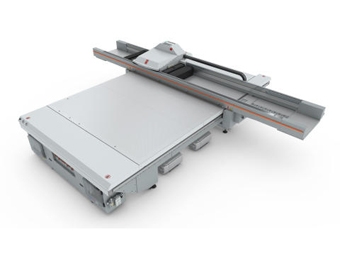

Comprised of the six-color Océ Arizona 6160 XTS device and the seven-color Océ Arizona 6170 XTS device, the Océ Arizona 6100 Series has been optimized for the efficient and high-speed production of rigid media applications. Designed as a dedicated flatbed system, the series features an extra-large 8-by-10 foot vacuum table to keep media and objects stationary during printing for optimal print quality and rigid media application versatility.

With a focus on pure productivity, the Arizona 6100 series’ true flatbed architecture supports a wide range of rigid media applications, including printing on odd-shaped, heavy, smooth or pre-cut rigid media; the production of high value, multi-layer applications; double-sided prints in perfect register; large prints tiled over multiple boards with perfect geometry; and edge-to-edge printing without hassle or mess.

“For users who require high-volume, rigid media printing capacity, these new printers deliver outstanding output quality at high speeds with the broad application range of true flatbed architecture, enabling users to potentially expand the boundaries of their service offerings,” said Junichi Yoshitake, senior vice president and general manager, Business Imaging Solutions Group, Canon U.S.A., Inc.

The flatbed table has two independent printing zones, each with its own vacuum system, for simultaneous printing and media loading/unloading. This means one board can be staged and ready while the other is being printed, enabling non-stop production. Alternatively, the two zones can be combined into one to enable 8-by-10 foot prints. Pneumatic registration pins help ensure a quick, repeatable, easy loading of rigid media in systematic register every time. Together with a high-flow vacuum system for effective pull-down of rigid media, it means that the operator needs only seconds to load even the largest boards in systematic register. With media loading this easy, a single operator can service two printers simultaneously, producing almost fifty boards per hour in Production mode.

With almost 27,000 piezoelectric nozzles in a seven-row printing carriage, the Arizona 6100 Series rapidly and reliably produces inkjet print output at speeds up to 1,668 square feet per hour. A newly designed Automated Printhead Maintenance System provides completely automated, hands-free printhead cleaning in less than 25 seconds per color, making the vast array of nozzles available and ready to print at virtually any time. Employing the same award-winning Océ VariaDot™ printing technology as all other Arizona Series printers, the Océ Arizona 6100 Series offers the same ‘near photographic’ print quality, while using light inks for reliable printing in even the fastest production modes. Finally Active Pixel Placement Compensation ensures that every pixel is adjusted to land exactly where intended for accurate, uniform print geometry over the entire flatbed.

The Océ Arizona 6160 XTS printers are easily upgradeable to the Océ Arizona 6170 XTS printer with the addition of one ink channel for white ink applications. Both Océ Arizona 6100 Series models will also support an additional ink channel for future development. A hardware/software interface allows for easy integration with third-party automation and workflow systems.

The Océ Arizona 6100 Series printers are available directly through Canon Solutions America.