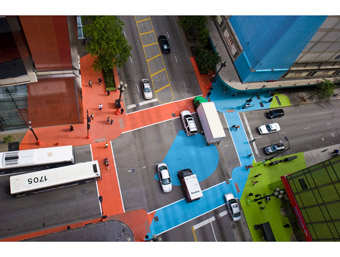

This past summer, massive swatches of color could be found covering a portion of Downtown Chicago, as the intersection and surrounding buildings at Adams and State Streets were decorated with a bright plethora of reds, greens, and blues. This vinyl display was all part of “Color Jam,” the city’s biggest large-scale public art project…ever.

This past summer, massive swatches of color could be found covering a portion of Downtown Chicago, as the intersection and surrounding buildings at Adams and State Streets were decorated with a bright plethora of reds, greens, and blues. This vinyl display was all part of “Color Jam,” the city’s biggest large-scale public art project…ever.

Color Jam was designed by well-known, local multimedia artist Jessica Stockholder as a way of showing “the imposition of colors interacting with the elements and daily chaos of a bustling city.” But not only was this artistic project a unique way of enhancing the city of Chicago and attracting visitors, it was also a colorful example of how to solve vinyl production and installation quandaries.

The Beginning

Earlier this year, the Chicago Loop Alliance (CLA), a business-supported organization, was put in charge of making this project a reality.

After interviewing a few firms across the country, CLA Program Manager and Curator Tristan Hummel recognized that Bloomingdale Signs By Tomorrow in nearby Bloomingdale, Illinois, had the know-how and capabilities to handle every aspect of this project in-house, so he hired them this past March. (Note: The sign shop had already created large-scale vinyl images for the Vancouver Olympics, as well as other high-profile graphics projects.)

After the CLA agreed on a proposal that took him six weeks to draw up, Gary R. Schellerer, president/CEO of Bloomingdale Signs, brought along Director of Operations Alan Schellerer and Installation Manager Patrick Perralt to the contract signing to discuss further ideas. “Alan really loves Chicago and the arts,” he says, “and Patrick is an excellent motivator.”

The end-result: More than 70,000 square feet of four different vinyl materials was used horizontally, vertically, and diagonally. A foil-backed adhesive film was used for the streets and sidewalks; a perforated vinyl to cover glass surfaces; a vehicle wrap vinyl to conform around traffic lights, light poles, flower pots, etc.; and a banner mesh to enhance the masonry of abandoned buildings, as well as the concrete around a CVS store.

The end-result: More than 70,000 square feet of four different vinyl materials was used horizontally, vertically, and diagonally. A foil-backed adhesive film was used for the streets and sidewalks; a perforated vinyl to cover glass surfaces; a vehicle wrap vinyl to conform around traffic lights, light poles, flower pots, etc.; and a banner mesh to enhance the masonry of abandoned buildings, as well as the concrete around a CVS store.

(Note: Stockholder originally intended to cover the entire intersection, but the city had some traffic safety concerns and limited this to applying color to crosswalks only and designing an oval pattern for the center of the intersection.)

Alan Schellerer admits everyone was a bit daunted when first hearing the details and scope of the project. “It was on a very large scale and very much in the public eye but with a limited budget and a tight timeline,” he says. “However at our first meeting, we expressed nothing but confidence in front of the client, while the ideas were being presented to us.”

Since the CLA was working within an already-tight budget, the organization also hired Gary Schellerer as general contractor on this project, where he not only rounded up vendors but also acquired signed release forms from property owners, management companies, and tenants in the area. “Originally they thought they would be printing and installing at multiple locations,” he says, “but since we could do everything ourselves, there was no need for that expense.”

Hummel secured permits and worked with Bloomingdale Signs By Tomorrow to manage all the bond work necessary. Meanwhile Bloomingdale Signs handled all the production, printing, laminating, painting (more on that later), and installing. “In total, we had approximately 180 hours of actual print time,” says Alan Schellerer. “Not only did [Perralt] coordinate the install, but he also oversaw the printing and production work and made sure everything was finished on-time.”

{2j_imageviewer 8}

Building and Window Wraps

For the red and green building wraps and glass windows along the intersection, Bloomingdale Signs printed fifteen 54-inch-by-300-foot rolls of Clear Focus® One Way Vision™ exterior-mount film using an HP Scitex XLjet 1500 printer. Clear Focus provided the film with a clear PET liner to accommodate the UV technology.

“When Gary mentioned the project to me, I was intrigued by the far-reaching opportunities of ‘colorizing’ an entire intersection in Chicago,” says Debra Liles, market development manager at Clear Focus.

{2j_imageviewer 9}

Banners

To create banners that would cascade down the focal Color Jam buildings and give a true three-dimensional look, Bloomingdale Signs By Tomorrow printed ten 16-by-150-foot rolls of 10 oz. Ultraflex UltraMesh Supreme material on its HP Scitex LX1500 wide format printer. With 25 percent air flow-through, this material allows wind to pass through panels without risking any tearing or loosening of the affixed banners.

Perralt and his team used their Miller Weldmaster Extreme 112 to weld sixteen-foot sections together to make five large building banners.

“Since this particular mesh has very small, slit-like holes, the holes don’t infringe much on the graphic/ad space,” says Jaime Giannantonio, marketing manager at UltraFlex, “so they were able to maximize the amount of color and ink on the building façade.”

{2j_imageviewer 10}

Ground Level

Bloomingdale Signs also wrapped light poles, flower pots, street signs, awnings, stone pillars, and anything else ground-level that could host colored vinyl.

To do this, Bloomingdale Signs printed thirty rolls of 54-inch-by-150-foot General Formulations (GFI) Automark™ 230-54 conform vinyl paired with GFI’s gloss and matte cast laminate on their HP DesignJet 9000 solvent printer. “This material is generally used to wrap vehicles, but they successfully used it here,” says Mike Clay, president of General Formulations.

According to Alan Schellerer, “Since the conform vinyl would be seen very close up, we refused to have any banding or visual imperfections on it. So even though it took four-and-a-half hours per roll, we made sure it was printed right.”

{2j_imageviewer 11}

Streets and Sidewalks

Since the intersection is subjected to 80,000 vehicles a day and power washings every other day, the CLA decided on Asphalt Art material for the crosswalks and sidewalks.

Asphalt Art is a peel-and-stick, aluminum foil-based floor graphic with inherent non-slip properties that’s designed for outdoor short- to medium-term use. It requires no overlaminate and can conform to cracks and crevices, as well as irregularities in concrete, asphalt, brick, pavers, etc. The product had already been used at finish lines for the Chicago Marathon and the Tour De France and even in pools (meaning it could definitely stand up to any wet conditions).

“They didn’t want any issues of someone slipping and falling on a material being used in this project,” says Mike Gillette, brand manager at Asphalt Art.

While graphic providers typically print UV inkjet images onto Asphalt Art, because these were two of the busiest streets in Chicago, the CLA knew touch-ups were going to be necessary and thought this would be easier to accomplish if the material were painted instead.

Gary Schellerer knew Debra Lucas, his long-time representative at digital solutions provider Milano Digital, had experience working with Asphalt Art and contacted her. “I researched the paints, purchased and tested the paints, and then sent the material to the manufacturer for them to test to make sure that we were within safety specifications,” she says.

During this conversation, Gary also mentioned his need to find a facility that could host a production of this size. Lucas immediately brought up the new large-scale contract warehouse her company had just moved into.

In this roomy warehouse, Bloomingdale Signs By Tomorrow employees unrolled thirty-one one hundred-foot rolls of Asphalt Art and, over three days, used rollers to apply the various colors of Benjamin Moore exterior-grade, epoxy-based paints onto the materials. (Note: This paint cures in twenty-four to thirty-six hours, which was a plus). They bought three times the paint needed, with future touch-ups in mind.

Bloomingdale Signs allowed all the unrolled materials to dry in the warehouse and then re-rolled them onto rolls using a slitter/roller machine, loaded them onto their truck, and took them downtown for installation.

{2j_imageviewer 12}

Installation

Installation covered seven consecutive nights. Alan Schellerer and Perralt worked from 7pm to 7am every night, yet their enthusiasm never wavered.

To help fit their budget, the CLA also enlisted a dozen volunteers to aid in the ground-level vinyl installation. Most of the volunteers were involved in the Chicago art community and were already fans of Jessica Stockholder. “They were all great to work with and had a great deal of artistic ability (which really helped),” says Alan. “They caught on very quickly.”

Bloomingdale Signs and the volunteers only applied graphics directly to the streets via heat guns on weeknights between 2am and 5am, since traffic was most minimal then. Cones and caution tape (and the occasional cop) also kept any oncoming traffic at bay.

The crew finished installing the intersection graphic at 4am on June 4. The catch: The opening ceremony was at 10am later that morning. “I had to drive home, shower, put on my suit, and head back down for it,” says Alan.

Completion

Completion

The Color Jam project has been a hit and even generated prominent coverage in local and national newspaper and television reports. Stockholder herself has been ecstatic that Bloomingdale Signs was brought on-board to bring her vision to full-color life.

The project is scheduled to run through the end of this month. Bloomingdale Signs has been handling any patching and painting of worn areas every other week during the duration of the project. “We’ll be removing all of the building graphics, while the CLA is going to be utilizing volunteers to remove all the ground-level graphics,” says Gary Schellerer.

The biggest challenge on this project involved color matching. “It was difficult to match three different colors on four different materials with three different types of inks,” says Alan Schellerer.

In the end, Bloomingdale Signs was honored to bring more color to the city of Chicago. It took every part of their business experience and what they’ve developed over the past twenty years to put this together—from their graphic designers and installers to print staff and sales people. “We were referred by a customer who purchased a small banner from us a couple of years ago,” says Alan. “It shows that great opportunities can be generated by even the simplest of projects.”

—Jeff Wooten