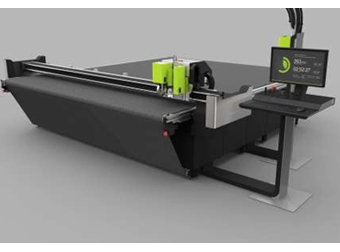

Acknowledging that the wide format digital printing world continues to rapidly escalate productivity that requires faster turnaround times on an ever-increasing variety of materials, Esko answers that trend with the introduction of a completely new Kongsberg digital finishing system, the “Kongsberg C”. The first model of this new platform, the Kongsberg C64, is first demonstrated at the 2013 SGIA Expo in Orlando, Florida (October 23-25).

Kongsberg C systems are the first fully-featured, super-wide digital finishing systems. “This is not scaled up from a light duty finishing table – it’s a completely re-engineered platform after a decade of the highly successful and well-known Kongsberg X-series,” comments Tom Naess, Esko product manager CAM. “We wanted to make sure that it was designed for 24/7 production and semi-industrial environments. Along with substantial flexibility, the new, wider format perfectly fits modern 3.2-meter wide format printers, working with wide rolls and wide sheets.”

A large, complete finishing system for large, diverse jobs

The Kongsberg C64 model works with 126-inch wide-by-126-inch long (3.210 mm by 3.200 mm) materials, perfectly fitting modern wide format printers. Also available is the Kongsberg C60 model, accommodating 126-inch wide-by-63-inch long (3.210 mm x 1.600 mm) sizes. Covering more than 10 feet across the table, a unique, extremely rigid, carbon-composite traverse beam assures excellent precision and supports high speed, fast acceleration, high quality creasing and exclusive, powerful 3kW milling capabilities. Thus, the Kongsberg C always produces high quality finishing results, with no left/right/middle variances due to traverse bending. Unlike other super-wide finishers, the Kongsberg C does not decelerate with demanding materials, handling the most complex jobs without sacrificing quality or throughput.

The Kongsberg C stands for Capability, Capacity, Consistency, Choice, and Complete:

• Capability: the Kongsberg C processes the widest variety of materials of any super-wide finisher, working with an extensive range of finishing applications and substrates from paper and textiles to corrugated up to triple-wall thickness (unique to the Kongsberg C), fluted board, plastics, aluminum composites, and more.

• Capacity: it has the highest throughput of any super-wide digital finisher. The Kongsberg C is also the only super-wide finisher to offer a 3kW continuous duty high-performance milling unit.

• Consistency: the Kongsberg C series delivers the same performance every time, even on the most demanding materials or the most complex jobs.

• Choice: there’s no need to choose between size and productivity. The Kongsberg C offers both, eliminating the necessity to own dedicated digital finishers for different applications.

• Complete: Esko offers a full solution consisting of hardware, software, bits & blades and services. The Kongsberg C series brings unmatched versatility with four “power” tool units and a full assortment of “speed” tools. The table can be upgraded to fit production needs as a business grows with additional tooling, a conveyer feed system, roll feeder unit and more.

A versatile finishing system to fulfill all production requirements

Just as impressive, the Kongsberg C offers exceptional versatility for all sign, display and packaging applications. New tool covers offer clean, fast changing of the full range of Kongsberg XP tooling. Customers no longer need to invest in different digital finishing devices for different applications. With its combination of dexterity and power, the Kongsberg C, one machine fits all production needs – rolls, sheets, corrugated, milling – offering a more effective and smaller footprint solution than having to own multiple systems.

Design and ergonomics: an easy to use finishing system

The new solution has not only been reengineered, also the design has been completely reworked to apply to highest standards of industrial design and meet the operator’s needs for ergonomics and safety. For a machine so large, the Kongsberg C is remarkably easy to use – from the new, simple interface to the ease of replacing interchangeable tools on the table, helping to reduce operator error.

The new workstation mounts on any corner of the machine. A new maneuvering concept places an integrated joystick and operator panel on the traverse. It can be mounted on either side of the table. In fact, to make it easier for another operator, a second operator panel can be added. For easy loading and unloading, the new conveyor option can be manually jogged in both directions.

“We have consulted our customers before and during the development of this new table and we are convinced they will appreciate to see that Esko now has the fastest, most productive solution at a super-wide width, with the greatest versatility in its size class,” concludes Steve Bennett, Esko Vice President, Digital Finishing Business. “The new Kongsberg C leapfrogs competitive tables on many ways. It simply enables us to provide the best value solution in this category.”

At SGIA, Esko is taking orders for the Kongsberg C finishing tables. The first customer deliveries are expected at the beginning of Q2, 2014.