When SloanLED 701507-MODW power supplies began experiencing problems in the field, the company had to figure out what was going wrong and how to get to the root cause of the failure quickly, in order to make sure their customers would have a reliable product. “We knew we had to be proactive and aggressive in addressing the problem and making it right,” said Steve Shotwell, general manager of SloanLED. “Our goal was not only to fix the problem, but ensure we were taking care of our customers who experiencing problems in the field.”

“I have been in distribution of electric sign supplies (transformers, ballasts, etc.) for over thirty-five years and have never seen any company step up to the plate the way SloanLED has,” stated Ed Della Valle, general manager at J. Freeman Distributions.

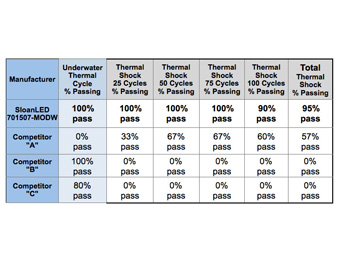

The analysis of the failed power supplies found that the cause was a series of solder cracks. “Thermal expansion and contraction was the root cause of the solder cracks” said Bruce Quaal, director of Engineering at SloanLED. To further back up the redesign SloanLED had Reliant Labs, the world’s largest HALT (Highly Accelerated Life Test) lab based in Sunnyvale, California, test SloanLED’s revised 701507-MODW power supply against three top industry competitors. The results show that 100 percent of the SloanLED units tested showed no signs of solder cracks after 75 cycles (158°F to -22°F to 158°F), the equivalent of 5.7 years.

In addition, 90 percent of SloanLED units showed no signs of solder cracks after 100 cycles, or the equivalent of 7.6 years of typical field use. This is compared to the closest competitor at 60 percent passing for 100 cycles and the other two unable to pass the first 25 cycles.

The power supplies were exposed to 150-degree temperature swings from -30°C to 125°C. The dwell time at each temperature extreme was 55 minutes, and the thermal transition rate was set to 6°C per minute going hot and 8°C per minute going cold.

Analysis consisted of powering each unit at high and low temperatures with a full load and checking for proper operation. The units were then cut open, the potting compound removed from the bottom of the printed circuit board, and all solder joints were examined under a 20X microscope for cracks. One or more solder cracks resulted in the test result being recorded as “failed.”

The tests also showed that 100 percent of SloanLED units showed no water intrusion after an underwater thermal cycle test. “The water ingress is pretty significant because this allows the sign maker to use the power supply in harsh, wet applications without the need for a cover or transformer box,” said Shotwell.

The power supplies were exposed to twenty temperature cycles from -30°C to 70°C while powered, fully loaded, and submerged in tubs of water. The dwell time at each temperature extreme was twelve hours and the thermal transition time was two hours from hot to cold. After twenty cycles (over twenty-one days), the samples were removed from the chamber and analyzed. If power supplies failed electrically during the test, they were recorded as “failed.”

All power supplies were then cut open and inspected for water ingress. Any water seen inside the power supply was recorded as a failure. The SloanLED 701507-MOD received 100 percent pass ratings. Only one of the three competitor products tested received a passing rating.

Any Reliant Labs test equipment that requires periodic calibration was in current calibration at time of the testing. The calibration certifications are traceable to the National Institute of Standards and Technology.

Quaal coordinated the efforts with Reliant Labs. “Their client list is impressive,” he said.

Quaal also visited their facility to check out their labs. “I came away comfortable they could perform the test competently and report on the results professionally,” he said.

Reliant Labs found that the robust 701507-MODW power supply is able to withstand the harsh environments of its stated operational temperature range and weather exposure. Qualification tests supported high reliability performance for solder quality, solder joint strength, and water ingress protection. “MODW units meet SloanLED’s stringent design criteria and outperformed the competition, making them best-in-class,” says Elmer Tolentino Jr., CRE, Principal Reliability Engineer at Reliant Labs.

Reliant Labs found that the robust 701507-MODW power supply is able to withstand the harsh environments of its stated operational temperature range and weather exposure. Qualification tests supported high reliability performance for solder quality, solder joint strength, and water ingress protection. “MODW units meet SloanLED’s stringent design criteria and outperformed the competition, making them best-in-class,” says Elmer Tolentino Jr., CRE, Principal Reliability Engineer at Reliant Labs.

For the past twenty-four months, SloanLED put more than 300,000 MODW power supply units into the field (installed on rooftops with the primary end threaded into a wet location junction box, inside sign housings, inside sign raceways, inside electrical enclosures mounted on a roof top, etc.). “We knew we needed to take care of our customers in an industry that unfortunately had some of these power supplies that didn’t work as well and failed prematurely,” says Shotwell. “We not only went as far as helping people with cost reimbursement to repair their signs, but we also encouraged them to replace units in ‘suspect’ manufacturing lots with brand-new fresh power supplies.

“We also developed our own program where we actually do the repair work if our customers want us to.”

The MODW 12 VDC power supply is IP68 (Ingress Protection) rated and extremely weather resistant. It carries UL recognition for dry, damp and wet locations, and is RoHS and WEEE compliant.

The latest version of the MODW includes improved stress tolerance in heat-related components and unique design elements that allow the components to flex to accommodate temperature-related expansion and contraction. “Thermal expansion and contraction is the root cause of the solder cracks,” said Quaal. “Even poor solder joints can survive if there is no force applied to them. These power supplies are fully potted.

“When the potting compound expands, it pushes against the aluminum extrusion. The aluminum expands very little. The potting compound has nowhere to go, so the pressure inside the extrusion increases. This means additional force is put on all the components and joints inside.”

Quaal notes that they couldn’t eliminate the pressure, so they had to increase the strength of the joints and increase the flexibility of the component mounting. “If the components can move without pulling or pushing on the solder joints, the joints will not see additional stress,” he said.

There were components mounted to structures inside the power supply as heat sinks and SloanLED developed ways to free those up so they could move when the potting compound expanded or contracted. “We upgraded some of those components and moved them around in such a way that we were able to dissipate the heat without securing it to the side of the case,” said Quaal. “When the parts inside saw the potting compound expanding and contracting, they could just move along with it.”

The MODW features a patented end cap design for easy electrical connections and installation. It is auto-resetting after an electrical short is corrected, eliminating the need to replace fuses or to reset a circuit breaker.

“This has not been an easy process, but all and all, I am confident in the performance of today’s MODW,” expressed Shotwell. “Our customers should have no concern using our power supply and our LED system. The proof is in the data.”