The EPL-HB-100LED-RT-UVA ultraviolet explosion-proof LED light fixture approved for paint spray booths from Larson Electronics provides operators with a powerful and energy efficient alternative to traditional luminaires with UV cutoff filters.

Traditional ultraviolet lights require a coating to block out visible light or a special composition of gases and chemicals used to create a higher concentration of ultraviolet light. LED lights are unique in that they have a narrower wavelength band than traditional ultraviolet sources and therefore do not require these special coatings. As a result, LED lights do not produce unused, wasted light and consume less energy than traditional UV lights on the market. LED lights are capable of producing very specific wavelengths with tighter curves and are more durable as well as lighter in weight.

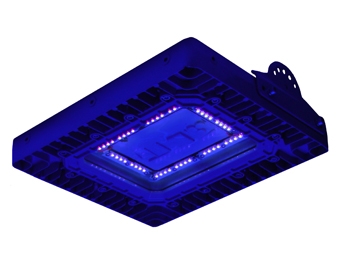

Lightweight and a low profile make this unit an attractive alternative to larger and heavier fixtures and require less hardware to install.

The copper-free aluminum alloy body is powder-coated for added durability and an attractive aesthetic appearance.

Special heat dissipating design in conjunction with LED technology helps this fixture achieve an excellent 50,000-hour rated lifespan with 80 percent intensity retention.

This fixture can operate on voltages ranging from 120V-277V and is ETL approved for use in wet environments and areas where UV lamps are used in paint and adhesive curing, food inspection, and for non-destructive testing.

“Our new 100 watt light fixture produces 35,000 mW of high output ultraviolet light in the UV A light spectrum,” Rob Bresnahan with Larsonelectronics.com said. “This new ultraviolet light fixture uses LED technology that is far better in energy savings than traditional UV bulbs and do not require the special cut off lens filters.”