As a manufacturer, LED spacing is probably one of the most common topics we are asked about, whether through layout requests or customer inquiries. Every sign is different, so it should not be surprising that there are a number of parameters that will impact LED spacing for an internally illuminated sign.

Sign Width or Stroke. Signs that require multiple rows or strokes generally require closer spacing, due to the lack of extra internal reflection from the side walls or return.

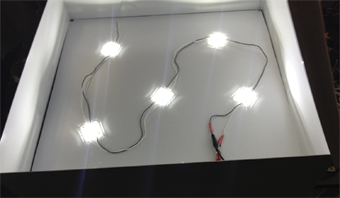

Can Depth. Deeper signs can allow for wider spacing between the LEDs, since there is more distance for the light to “mix” (thus preventing hot spots). However less LEDs means less total lumens, so there is a practical limit that keeps in mind the need for adequate brightness.

Face Material and Vinyls. Acrylics and other materials can have varying degrees of transparency. Materials with low transparency may require more LEDs or closer spacing in order to provide enough brightness.

On the other side, materials that are highly translucent may require less brightness but need closer LED spacing to provide an evenness of illumination.

Once the sign type and materials are known, it comes down to choosing the right LED module. Most LED manufacturers have density guidelines recommending the maximum stroke between rows based on the various sign parameters.

In the early days, many LED modules used 5mm type lamps. These lamps had some benefits because the epoxy-casted lens could be readily changed to provide different beam angles (10°, 30°, 60°, 165°, etc.). This gave the manufacturer a lot of flexibility to design modules that were optimized for different sign depths and strokes.

The problem with 5mm lamps is that the only place to dissipate the heat is through the bi-pin leads, which limits both brightness and longevity of the lamp (less than 10,000 hours).

As the focus moved to higher current, longer life LED lamp surface mount devices (SMDs) became standard; in fact, they are still the most common type of LED lamp sold today for sign modules. Most of these lamps have about a 120° beam angle (plus or minus 20 degrees).

These “standard”-type modules work well in five-inch (or greater) depth signs at five- to eight-inch row spacing and fit well with form factors established by their neon predecessor.

There is also some great software available to provide quick and accurate layouts for illuminated signs. One example is LED Wizard (a variation of Neon Wizard) from Aries Graphics (www.ledwizard.com).

According to Aries Graphics President Jeff Fassett, “The overall goal of LED Wizard 7 is to create a layout of modules that provides even lighting across the sign face. The four parameters that drive our layout software is stroke coverage for a single row, linear density (i.e., module per foot), clearance or distance of the modules to the return, and module rotation.”

LED Wizard 7 contains “Density Guidelines” from LED supplier partners so that, for a given stroke width and can depth, a clearance value and a certain number of rows are entered for an auto population. This takes some of the guesswork out of determining the correct population density and can save a lot of time in choosing the right product and spacing.

But what about non-standard sizes? Most questions regarding LED spacing that I see are for signs outside of this traditional five-inch depth:

• For large and deep channel letters (multi-stroke and greater-than-eight-inch depths), a number of manufacturers have high-output backlit modules available. Spacing for these letters depends more on getting adequate brightness than evenness of illumination. These products typically use larger and brighter LEDs and the spacing can be as wide as twelve inches at these depths. Their advantage: Reduced installation time versus peeling and sticking hundreds of lower output modules.

Many manufacturers also offer specific backlit systems for single- and double-sided cabinet signs, while others offer a separate extrusion to mount the modules into cabinet signs.

The other approach for cabinets is to mount the LEDs on the return. While many of these products use costly optics to “carry” the light into the sign, the cost can be justified due to the fact that the products produce a large number of lumens, and hence, less modules are required. (Note: It also reduces labor and the need for baffling or adding a mounting rail in double-sided cabinets.)

Spacing and/or the need to mount on one, two, or all four sides can vary. I recommend referring to the manufacturer’s recommended guidelines and, where possible, testing the material in the sign by temporarily placing the modules prior to permanent assembly.

• The second spacing challenge is in shallow cabinets and/or small channel letters (two- to five-inch deep).

This depth presents a problem for traditional SMD devices. The initial fix by manufacturers was to simply use smaller, lower profile modules with very close spacing (3.5 to 6) modules per foot. Examples of these products include: US LED’s Tadpole, CAO Group’s LuxemBright® Sizzle, Principal LED’s Eco Flex, and Permlight’s Nano. These products seem to work well in small, single-stroke channel letters that are two to five inches deep.

However when more than one stroke is needed, the materials can hot-spot at conventional row spacing. The only way to compensate is to reduce the row spacing. But doing so can increase installation time and, in some cases, cause the sign to be too bright.

A number of LED providers have been active in developing modules with wider beam angles to provide more evenness of illumination in multi-stroke letters and single-sided cabinets (three to five inches deep).

SloanLED and International Light Technologies utilize SMD LEDs that are mounted to emit light perpendicular to the face. Sloan V-180 Series LED directs light out of the sides of the module in a 180° beam pattern and can handle five-inch row spacing at three- to four-inch depths on standard sign faces.

Both GE and AgiLight have incorporated special optics into their modules that produce a batwing-type light profile. Both utilize lenses that preferentially send light out to the sides, while some of the light still goes out directly to the face of the sign.

These batwing modules are especially useful in multi-stroke signs at three- to five-inch depths where they can evenly cover up to ten- to twelve-inch row spacing. This can significantly reduce installation time and power consumption.

It should be noted in any of these products that emit more light to the side that most spacing or density guidelines are based upon providing even illumination. Since much of the light in these non-traditional designs is forced laterally, there is less light hitting the face directly; therefore brightness should be considered when determining adequate row spacing.

According to Fassett, “The trend towards populating with fewer modules that are brighter and more diffused points even more to the importance on the precise positioning of the modules, since there are fewer modules lighting a larger area.”

While rules of thumb can be used for traditional channel letters, it is important to use all of the resources available (software, manufacturer’s density guides and estimates, etc.) to make sure that the sign is bright and evenly lit when it goes up and the sun goes down.

Blake Vincent has been selling LEDs specifically to the sign industry for over ten years. Blake has a B.S. in Business Administration from Angelo State University and is a managing partner at Principal LED (www.p-led.com).

By Blake Vincent. Blake has been selling LEDs specifically to the sign industry for over ten years. He has a B.S. in Business Administration from Angelo State University and is a managing partner at Principal LED.