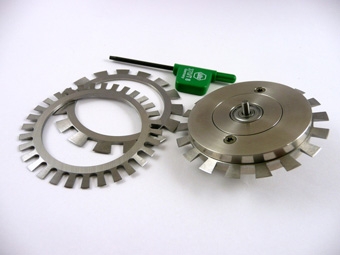

Esko announces a new range of Kongsberg tools is available for customers. On top of the more than hundred high-quality cutting blades, router bits, and accessories, some of the newest tools include a psaligraphy (paper cutting) knife tool, perforation wheel (pictured), and Braille tool. All three tools are available for usage on the Kongsberg XN, Kongsberg V, and Kongsberg XL Series of digital finishing systems.

Celebrating its golden jubilee this year, Esko Kongsberg built a strong foundation with the right technology and skills to help customers take full advantage of the opportunities digital finishing offers in the signage, display, and packaging markets. The broad portfolio of Kongsberg cutting tables caters to the different needs and speed in various segments of these markets.

But the wide variety of tools is what truly enables customers to extend their offerings and expand their businesses with the most creative use of materials and applications. Producers of packaging, displays and signage are used to work with a variety of substrates, ranging from foam, plastics, and vinyl to paper, corrugated boards ,and folding carton. And ever more materials are being added to the portfolio, including glass, wood, aluminium and textiles – opening up new markets and new applications.

To keep up with these new demands and further improve existing solutions, Esko Kongsberg has an experienced R&D team constantly developing new tools. High performance linked to high precision is what makes the difference here.

Today Esko Kongsberg already offers more than one hundred different cutting blades that are optimized for a very broad range of materials and applications. But there is much more these cutting systems can do when equipped with crease wheels, crease blades, milling bits or plotting pens.

Three examples of newly developed tools that extend Kongsberg capabilities are:

* The new Psaligraphy (or paper cutting) knife tool that cuts out the finest details in paper and folding carton, at a level not seen before. This is a perfect tool for adding creativity and value to greeting cards, promotional items or folding carton samples.

* The 60 mm Perforation wheel (pictured) enabling users to create tear and crease-assist perforations in corrugated board up to 4 mm thick at a much higher speed than before. This tool is ideal for producing POP-materials and all kinds of packaging. Prior to this wheel becoming available, it took about 40 seconds to do 1 meter of a 3×3 perforation pattern (3 mm cut and 3 mm space). The new wheel only needs two seconds to do that, quite a time saving!

* The Braille tool, loaded with clear acrylic ‘Braille spheres’ that are inserted into small holes. These holes are milled with a special spindle to create raised dots that are readable with fingertips. The Braille tool will work on most rigid materials more than one mm thick and is used to produce signage requiring directions or inscriptions in braille.

Esko’s online Kongsberg store for bits, blades and other accessories offers all the certified consumables for the full range of digital finishing tables at www.esko.com/store. More Esko customers find their way to the store every day, relying on Esko’s expertise to help them expand their business.

“Thousands of customers worldwide use our Kongsberg tables for a wide variety of applications and materials,” concludes Knut Johansen, Product Coordinator Esko Kongsberg. “We offer total solutions in digital finishing and are continuously developing and improving tools for new applications and substrates. Our research and development teams are offering innovation and support to expand the tooling range to bring even more value to the cutting tables.”