Sign shops own some big-ticket equipment, so the goal is to have the machinery in constant use and making money. In order to achieve that goal, shops are always on the lookout for new profit avenues. One such avenue might just be package prototyping.

JetComp Films has been providing a line of films for package prototyping for almost nine years, but it’s had its eye on the market for much longer than that. It wasn’t until the technology and quality of UV printers improved and white ink was added that they saw a chance in the digital printing market.

JetComp first partnered with Mimaki, but they have since worked with many of the major printers, including Epson, Roland, Ricoh, Mutoh, and FUJIFILM. JetComp offers a variety of flexible films that are compatible with UV, solvent, and latex printing. (Note: For more structural prototypes, JetComp Films can be laminated to boards and other stock.)

Fitting In

So what sign shops should take a second look at this market? Ones that do a lot of P-O-P displays are great candidates.

“If the shop’s involved in that point-of-purchase area, it already has some sort of a client base that’s involved in marketing and branding,” says Troy Edhlund, vice president of JetComp Films. “It becomes an added value that the shop can just do more for them now.”

Prototyping allows shops to go beyond signs with their P-O-P clients and gets them involved earlier in the graphics project since prototyping isn’t just for packaging—it can also be for product displays. “This gets them in the door to work with them a little bit earlier,” says Edhlund.

Existing Equipment

Getting started doesn’t require much of an investment outside of the materials, since shops that specialize in P-O-P signage typically already have the equipment they need—a cutter, a laminator, and a digital printer.

“It’s just a matter of plugging the media in and then setting up the proper print profile,” says Edhlund. “There are print profiles that you can use that are readily available for you to start out with. We even found good-old, generic glossy photo paper will get you started.

“Otherwise certainly any of the clear PET window film profiles will give you a good base point to work with.”

On the front end, shops don’t need to worry too much about color management like they would for a typical sign job. This is a prototype and not the final product.

“When you’re talking about market research and client presentation, minor color shifts don’t seem to bother them too much,” says Edhlund. “It’s a digital output device, and in the solvent inks, you’re working with extended color gamut in the first place.”

That expanded color gamut is one of the differences between an eco-solvent machine versus a UV or latex machine.

“[Solvent] will print finer detail,” says Edhlund. “If you take your average technology that’s out there now, you get down into six-point type, barcodes, etc.”

UV printing offers a higher opacity of white ink and is good for direct printing, luxury packaging that calls for special effects (like varnish or embossing) and specialty-colored stocks, since the ink is laid on top of the film.

“The UV tends to print in layers, so it gives you kind of a textured feel,” says Edhlund. “Whereas with the solvent inkjet, it jets into the membrane that we have mounted on our films, so you get this smooth, even finish that looks like the actual product on the shelf.”

With latex, the ink is also jetted on the surface of the film but with less than a three-micron dried ink layer, so the prototype remains flexible and doesn’t have a layered look or feel. Latex printers also offer the largest color gamut and a white opacity similar to UV.

(Note: While latex and UV can be used to an extent, solvent printing is the best choice for shrink sleeve packaging applications.)

No matter what printer a shop elects to use, “the key issue is that you have the ability of printing white ink,” says Edhlund.

The Price is Right

Shops may find that they’re familiar with much of what goes into package prototyping—except for the higher media price point.

“If you compare the price of our media to your traditional signage stuff, we are ungodly expensive,” says Edhlund, helping to put this into perspective. “But if you compare it to what prototyping has been before, you may spend $800-$1,000 for that one potato chip bag,” he says. “If you had the equipment in-house, you would use maybe about $8 worth of our media to make that one potato chip bag.”

So how does a shop price a prototype? Edhlund recommends putting a fixed fee on the file prep work the shop will have to do on the front end. The shop should then add that to the media cost.

“If you’re supplying it to them in the flat, and the customer’s just going to assemble it themselves with double-sided tape,” he says, “I tell them to go ten times your media cost.”

For shops interested in more information about breaking into package prototyping, JetComp will continue to add resources to its Web site—how-to videos on how to do shrink sleeve packaging, how to assemble a bread bag, and how to do a stand-up pouch. Reference materials on professional sealing equipment are also forthcoming.

By Ashley Bray

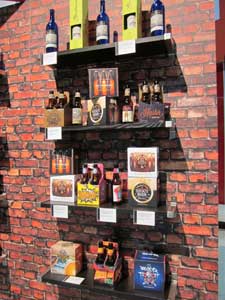

Photos (top to bottom): JetComp Films; Mimaki