Paint is ingrained in the sign industry more than any other product. Pinstripers and hand-painted signs are the roots of the industry, and paint still holds an important place today, even as digital processes and graphics have gained ground.

Sign Builder Illustrated recently conducted a survey, in conjunction with Sherwin-Williams Automotive Finishes, of almost one hundred sign shops to get a better picture of the role paint plays in today’s industry.

One of the first things the survey brought to light is a shift in the types of paint used by shops. Acrylic enamel (71.7 percent) and latex (69.8 percent) still top the list, but polyurethanes (64.2 percent) are not far behind. (Note: Most shops reported using more than one type of paint or coating.)

“We’re now seeing a trend away from older exterior technology of acrylic enamel and traditional latex house paint quality to higher quality coatings such as polyurethanes,” says Dan Szczepanik, Sherwin-Williams Fleet & Manufacturing marketing director. “Not only do polyurethanes provide better gloss and color holdout, they provide a wider palette of colors from which designers and manufacturers can choose.”

Just how much paint are sign shops using? The survey found that a majority of shops (89.4 percent) use one to one hundred gallons a month.

Szczepanik says most solvent-born paints have long shelf lives of five to eight years. Of course, whether a shop stocks paint or has an in-house mixing bay all depend on frequency of use and the size of the business.

For smaller shops that don’t use enough paint to justify stocking or a mixing bay, ordering paint on an as-needed basis from a paint shop or supplier can be the more efficient option. Plus sign shops can order just the amount they need—a pint, quart, gallon, etc.

For medium- to high-volume paint users, Szczepanik recommends using automatic mixing systems to avoid waste. “It will automatically mix the hardener with the color, and you only use the exact amount that you need,” he says. “When you pull the trigger, that’s when it will mix the paint; then once you’re done, you probably have a couple ounces in the line. But other than that, no waste whatsoever.

“It’s a great way to reduce your paint usage, eliminate waste, and save money.”

Saving money and reducing waste is important to sign shops as price came up as the highest rated item (28 percent) for things paint suppliers could improve upon.

Szczepanik points out that the ROI on paint actually makes it the more cost-effective option in the long run, since it’s meant to last ten to twenty years with no need for maintenance or replacements.

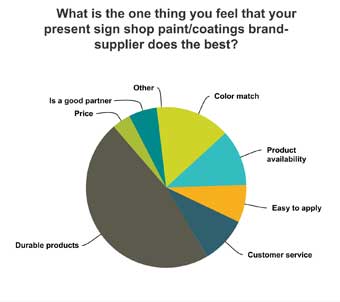

In fact, that durability came up as the top response (47.2 percent) for the thing shops feel their paint suppliers do best, and as the second highest rated attribute offered by paint suppliers.

Szczepanik says when shops are considering what products to use for a job, vinyl decals and pigmented plastics will have long-term durability in northern climates and on north-facing buildings. However farther south (where the UV rays are more intense), the durability of these items will suffer and paint becomes the better choice.

“Vinyl decals provide great durability against shrinking, cracking, and peeling but have limited UV protection. Many sign manufacturers shy away from decals with high exposure to the sun,” he says. “Pigmented plastics also provide a great alternative, but durability can be a concern depending on the pigments, additives, and types of plastic used.

“2K urethane paints will provide the most durable color and gloss retention, much better than vinyl or pigmented plastics.” (Note: 2K, or two components, means the paint requires an activator to dry.)

Of course, paint isn’t always the right solution, no matter the climate. Szczepanik says paint isn’t the best choice for intricate or detailed graphics or for short-term signage jobs.

Aside from durability, product availability came in as the third highest-rated attribute that paint suppliers offer.

“Fast or immediate paint product availability is critical due to shorter lead times on projects,” says Szczepanik. “Getting the right color the first time with excellent longevity and a quick turnaround makes it much easier on the sign manufacturer to streamline their production process.”

Rounding out the top five of the highest rated attributes were “easy to apply” and “easy to mix.”

“Better streamlining and flow means better cash flow to the bottom line,” says Szczepanik. “Quicker dry times, shorter or no flash times, one coat coverage, simple mix ratios—it all adds up to increased throughput and increased profits.”

The top-rated attribute that paint suppliers offer should come as no surprise—color match. Color match also came in as the second-best thing that paint suppliers do (13.2 percent).

“Color is king when establishing a corporate identity,” says Szczepanik. “You most closely associate certain brands with specific colors, so it’s critical those colors are exact matches when sign manufacturers mix and spray their paint for the job at hand.”

The importance of color doesn’t seem to be fading anytime soon either, as Szczepanik sees many color options and trends entering the market.

“You’re getting away from just your standard solid color coatings,” he says. “We’re looking at more complex metallics, micas, and pearls.

“You’re seeing all those effect colors now show up in the sign industry, and you’ll probably see that color development grow over time and get more complex.”

By Ashley Bray