Plotter-cut and print-and-cut heat transfer films are cost-effective alternatives to screen printing for shorter production runs and the personalization of garments. Many sign makers have discovered that making customized T-shirts and sweatshirts for their local sports teams, church groups, fraternities, and sororities is a great way to ignite their revenues at high-profit margins.

Plotter-cut and print-and-cut heat transfer films are cost-effective alternatives to screen printing for shorter production runs and the personalization of garments. Many sign makers have discovered that making customized T-shirts and sweatshirts for their local sports teams, church groups, fraternities, and sororities is a great way to ignite their revenues at high-profit margins.

What’s more, the investment to tap into this market is minimal. If you already have a printer or plotter, you need little more than a heat press. And you will need to do some homework.

With so many makes and models of heat presses, selecting one is usually confusing. To make the right purchasing decision for your business, you need to thoroughly investigate your options.

Start by asking the right questions

The most important one revolves around your projections for business activity. How frequently will you use the heat press? If you anticipate a steady stream of business, you’ll need a higher end, very dependable heat press from a reliable manufacturer to satisfy your capacity requirements.

If you intend to use the heat press frequently for long periods of time, you will need to turn your attention to an automatic press rather than a manual one.

One of the critical variables in heat pressing is pressure. On a manual press, pressure is regulated by turning a knob. An automatic press features pneumatic cylinders, which precisely control pressure in pounds per square inch.

Electrical requirements

On the higher end of the product range, heat presses are generally 220-volt. These units consume less energy, but cost more.

Other heat presses are 110-volt and will plug into a standard wall socket. That could be important if you’ll be transporting a press from one industry event to another.

Platen size

For most T-shirt work, a medium-size 16-by-16-inch press is adequate. It’s big enough to do most jobs yet small enough to transport, if you’re going to fairs, tradeshows, or industry events.

The best advice when selecting a heat press is to buy the biggest one that you can afford and that satisfies your specific needs. If you’re shopping for an in-shop unit that you won’t move once it’s in place, a 16-by-20-inch heat press makes the most sense. The larger platen size will allow you to conveniently align and press larger T-shirts.

The downside: A press with a larger platen size will likely weigh more. In fact, some units weigh more than 150 pounds. It’s great to buy a model that’s built like a tank, but when the heat press weighs as much as one and you need to transport it from place to place, you may want to take weight and size into consideration.

You may also want to inquire if the lower platen is removable and replaceable. Some swing-away units, for example, have removable platens with very small platens for mugs and caps. With this feature, one press can perform the work of two.

Equipment controls

Different heat transfer films require different time, temperature, and pressure settings. With this in mind, it’s easy to screw a job up, especially on a busy day or when layering different types of films on a garment.

The more sophisticated heat presses have controllers that can be programmed to remember the right settings for the material that you’re using. Some of these intelligent controllers have as many as seventy programmable presets.

Equipment style

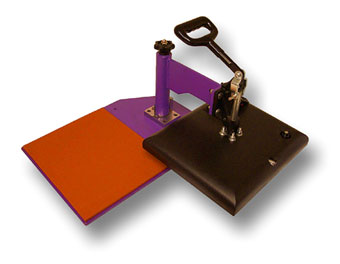

The two most popular heat press styles are the clamshell and the swing-away. On a clamshell unit, the lower platen is stationary, and the top platen moves up and down.

On a swing-away heat press, the top platen lifts straight up and then swings to the side. While small swing-away presses are available, a common size is in the 16-by-20-inch range.

Clamshell presses are popular for several reasons. Simple in design, these presses require less floor space, weigh less, and are more affordable than other designs. If you’re just starting out in the T-shirt business, a clamshell press could be a good choice for you.

In selecting the model for your shop, check to see how wide the clamshell opens. Some open as wide as 90 degrees, which is a good deal because it puts more space between your knuckles and the hot top platen.

So if a clamshell is such a great deal for sign shop owners, why would anyone consider a swing-away heat press? If you’re working with this style of equipment, your forearms aren’t exposed to the heat all day long (meaning you’re less likely to burn yourself). That’s a nice feature, but it will cost you more.

The swing-away design also provides for uniform pressure from the front of the platen to the back. Because of the design of some clamshell presses, the pressures can be greater at the back of the unit than the front. This usually isn’t an issue when pressing T-shirts. But uneven pressure could be problematic when pressing thicker garments, such as sweatshirts.

If you need a portable heat press, a swing-away model isn’t a good choice. Even the lighter models can weigh as much as a hundred pounds. Manual or pneumatic pressure

Manual or pneumatic pressure

An automatic pneumatic press sounds great because the pressure settings are consistent and their performance is reliable. Remember though that pneumatic means that the press needs air pressure. That means that you’ll need a compressor. Most sign shops may want to stick with a press that uses a manual pressure knob.

Warranty

While money is always a consideration, you should only buy a unit that best satisfies your production requirements and the one that you can afford. And don’t forget to ask the sales person about the warranty on the heating element, the frame, and the electronic controls. Warranties vary from one manufacturer to another and from one model to the next.

Photos (top two) courtesy of Geo Knight & Co; bottom photo courtesy of Dave Forrest.